The Solution

Tailored to address their specific needs and challenges, a remote maintenance program emerged as the optimal solution for the company. The introduction of wireless sensors, such as Sparrow, struck a perfect balance between affordability, performance, adaptability, and remote diagnostic capabilities.

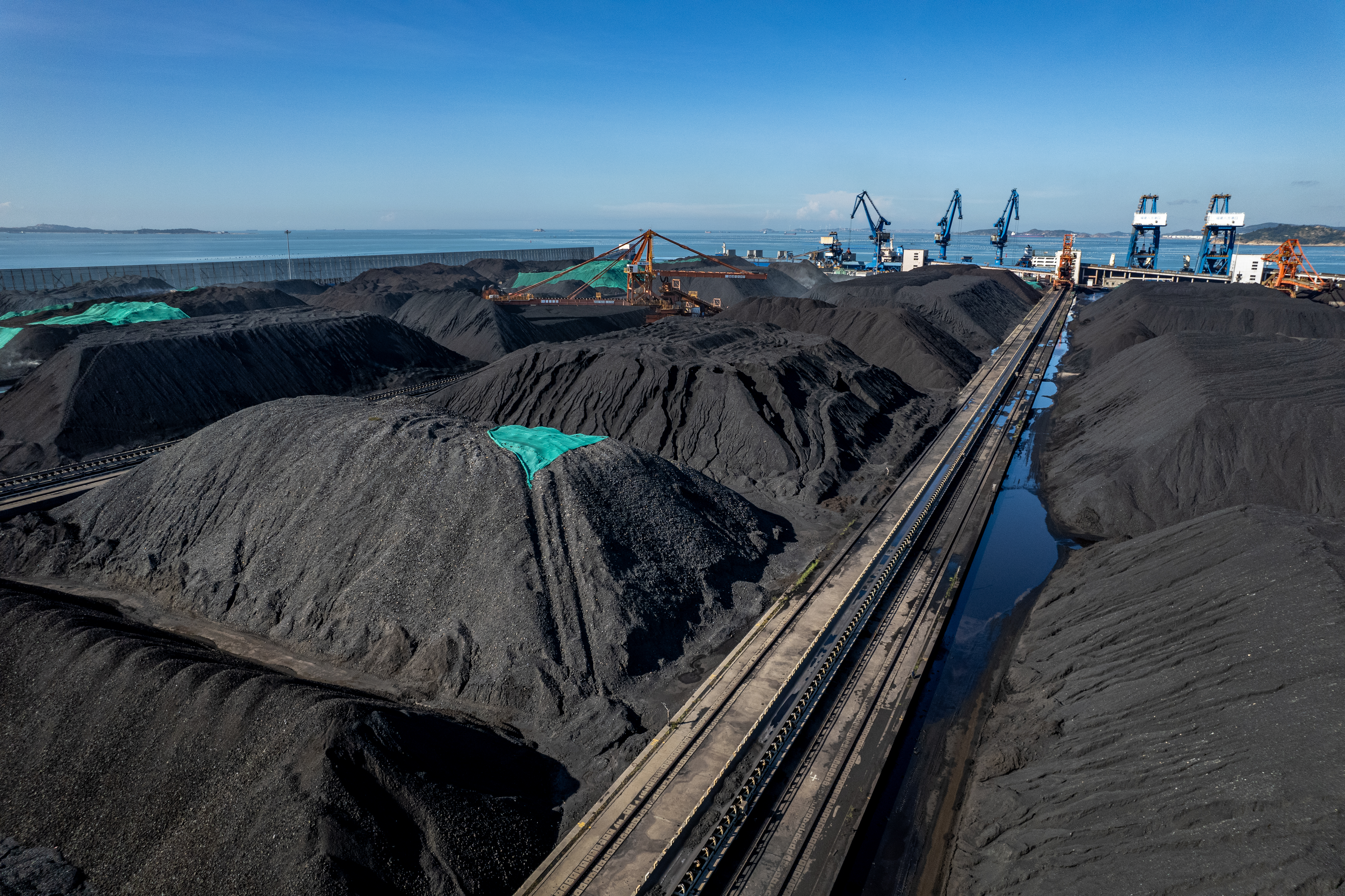

Deploying two hundred Sparrow sensors along the approximately 4-kilometer conveyor belt allowed for real-time monitoring of the machine’s health, covering its entire length, from start to finish. This approach minimized the risk of breakdowns, ensured uninterrupted operations and guaranteed the entire safety of the employees.

Furthermore, the Sparrow wireless system seamlessly integrates with the Falcon portable data collector and MV-x online monitoring system within NESTi4.0. The newly introduced, NEST Vision, offers the company a comprehensive view of its extensive machinery network, accessible directly from their centralized diagnostic center. This integration goes beyond mere basic alarms and trends; it delivers actionable insights that streamline informed decision-making processes while ensuring oversight of every asset, regardless of the monitoring tool used.

The Outcome

By integrating hundreds of Sparrow units into their existing reliability tools ecosystem, they have significantly improved both production output and safety protocols at their site. This strategic move, coupled with the comprehensive insights provided by NEST Vision, streamlined their predictive maintenance approach. This advancement represents a pivotal step in enhancing the overall reliability and performance of their site. With newfound predictive capabilities, they can navigate operations with unprecedented confidence.

Leveraging the suite of Acoem reliability tools (including Falcon, MV-x, Sparrow, and NEST Vision) has revolutionized their maintenance management practices. Now equipped with a unified platform, they can oversee all site equipment from a single interface, effortlessly schedule maintenance tasks, and make well-informed decisions with clarity.

As they continue to expand their operations, with machinery spanning vast distances and encompassing various types, the prospect of incorporating additional MV-x for their car dumper further emphasises their commitment to cutting-edge reliability solutions.