Bearing greasing assistant

The Bearing Defect Factor™ is the perfect greasing assistant for your rotating machines

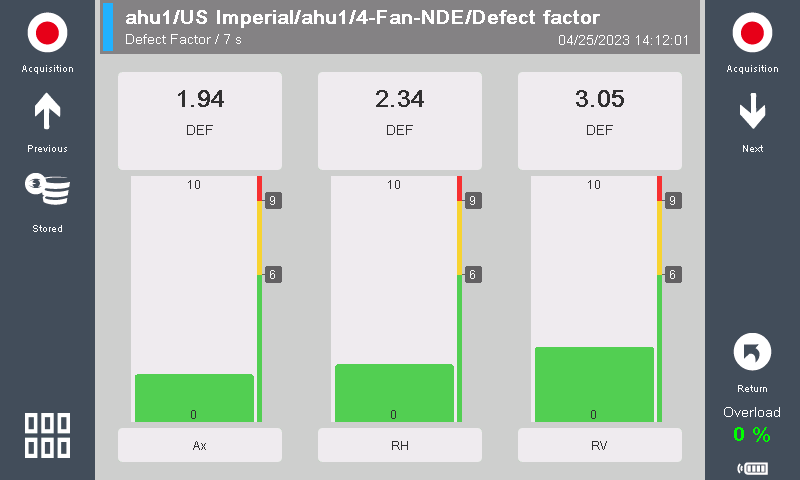

Discovering Bearing Defect Factor ™ on Bearing Defender App and SMC

Acoem’s algorithm Defect Factor™ (DEF) is directly integrated into the Acoem Bearing Defender Application and Acoem SMC. Customizable across a broad range of industries worldwide, the DEF indicator offers specific guidance during your greasing process. Discover more with the application note in the “resource” category of the Bearing Defender App and Smart Machine Checker (SMC).

Features

Bearing Defect Factor™

The DEF indicator measures high-frequency impacts that occur when a bearing is not properly lubricated with grease, and is represented as an absolute value ranging from 0 to 12

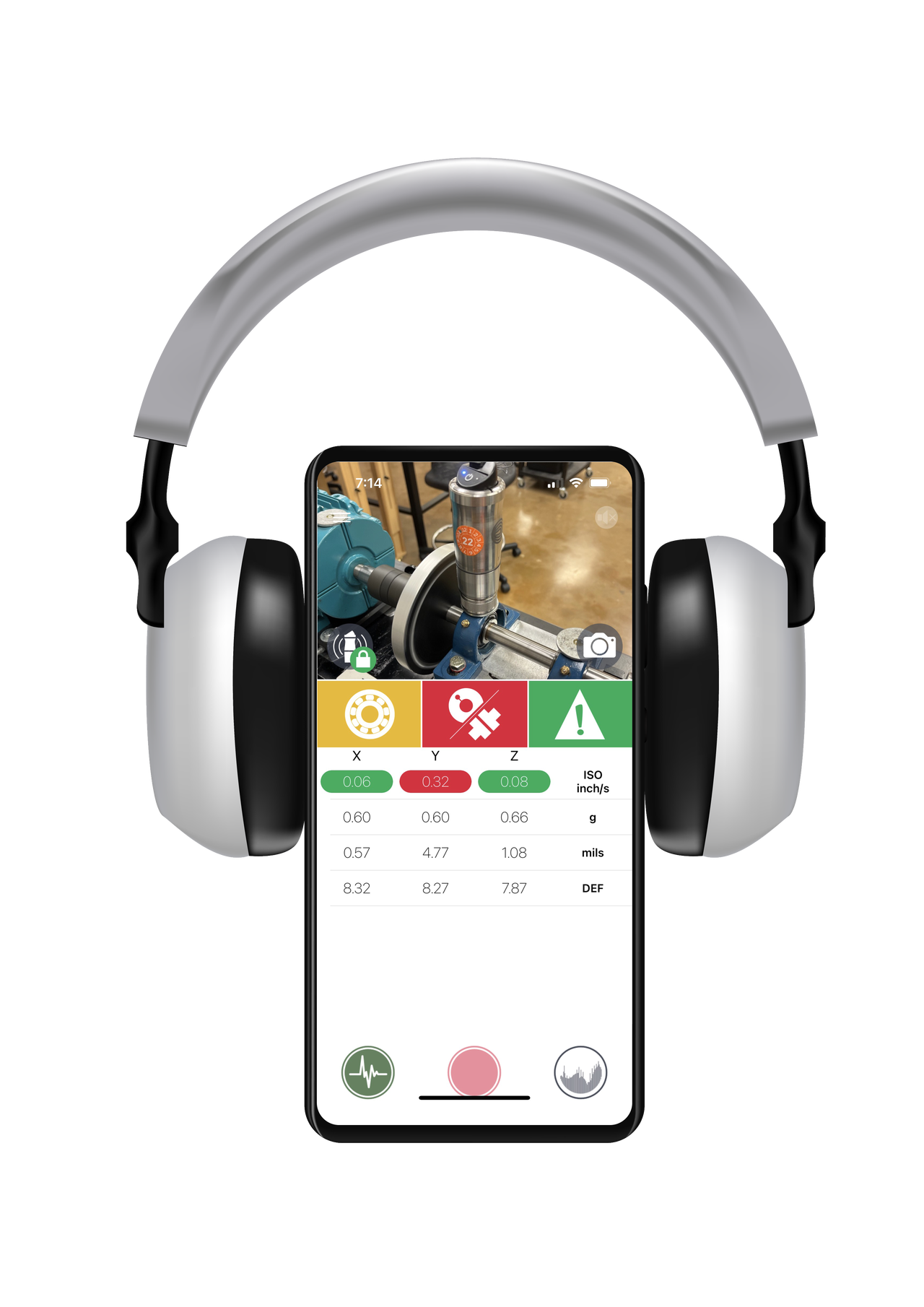

Audio Listening

Connect your headphones and listen to the real-time decrease in noise of your rotating assets while greasing

Wireless measurements

Patented wireless vibration measurement (US 9,921,136) provides the best user comfort and experience with live-streaming capability and a rechargeable battery for an 8-hour measurement activity cycle