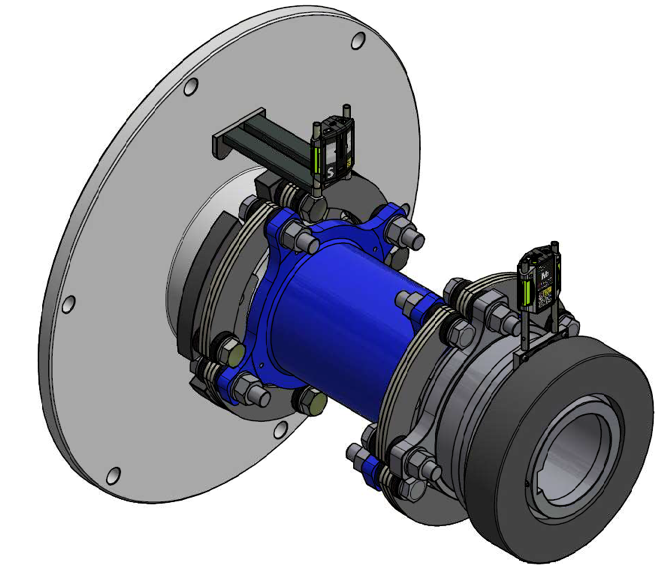

EVO ACCIONA

Shaft alignment in the wind power Industry

The EVO ACCIONA is custom-made with firmware and fixtures designed specifically for Acciona turbines. These precisely designed fixtures make generator-to-gearbox alignment easy inside any nacelle – safeguarding reliability and optimizing the energy efficiency of the wind turbine.