The Challenge

A rolling bearing is one of the most widely used elements in rotating machinery. As a critical component, it carries most of the load during the running of rotating machinery. If rolling bearing fails, serious problems arise, which will in turn result in the decrease of production efficiency and large economic loss. Records show that faulty bearings contribute to about thirty percent of failures in rotating machinery. Thus, it is of great importance to address effective fault diagnosis for rolling bearings.

Wonder Cement, a trusted brand and one of the leading cement manufacturers in India has always focused on digitalization as a corporate strategy. As a part of the initiative, they have collaborated with Acoem India as their condition monitoring partner for predicting maintenance and reducing unexpected shutdowns.

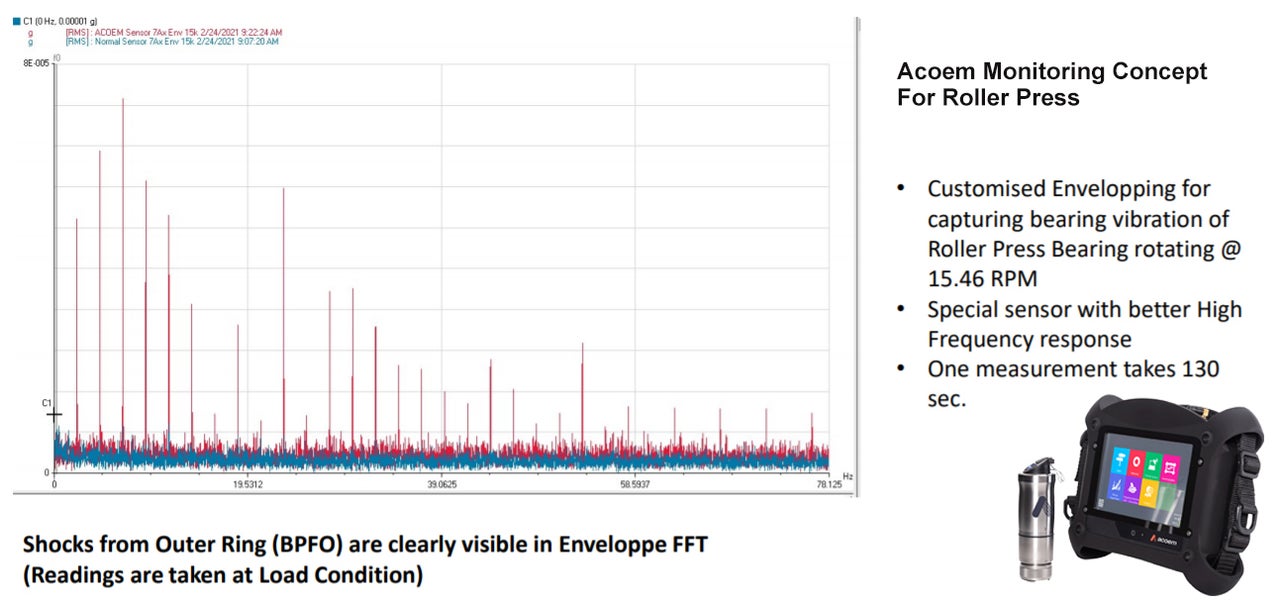

They have been monitoring their roller presses using conventional monitoring technologies. The client was worried and skeptical regarding the extent of bearing damage and with the present setup, it was difficult and challenging to get a definite outcome.

Early bearing fault detection was challenging because of the slow turning speed of HPGR (15-16 rpm) and high frequencies caused by the crushing process. The existing conventional monitoring methodology had limitations and could not support in providing actionable data to differentiate between these similar frequency patterns.

Additionally conventional techniques of vibration analysis, based on the frequency domain, have shown their limit for low speed rotating parts, where faults can result in very low energy phenomenon and are hardly detectable.