AT-100

An app-based solution for shaft alignment

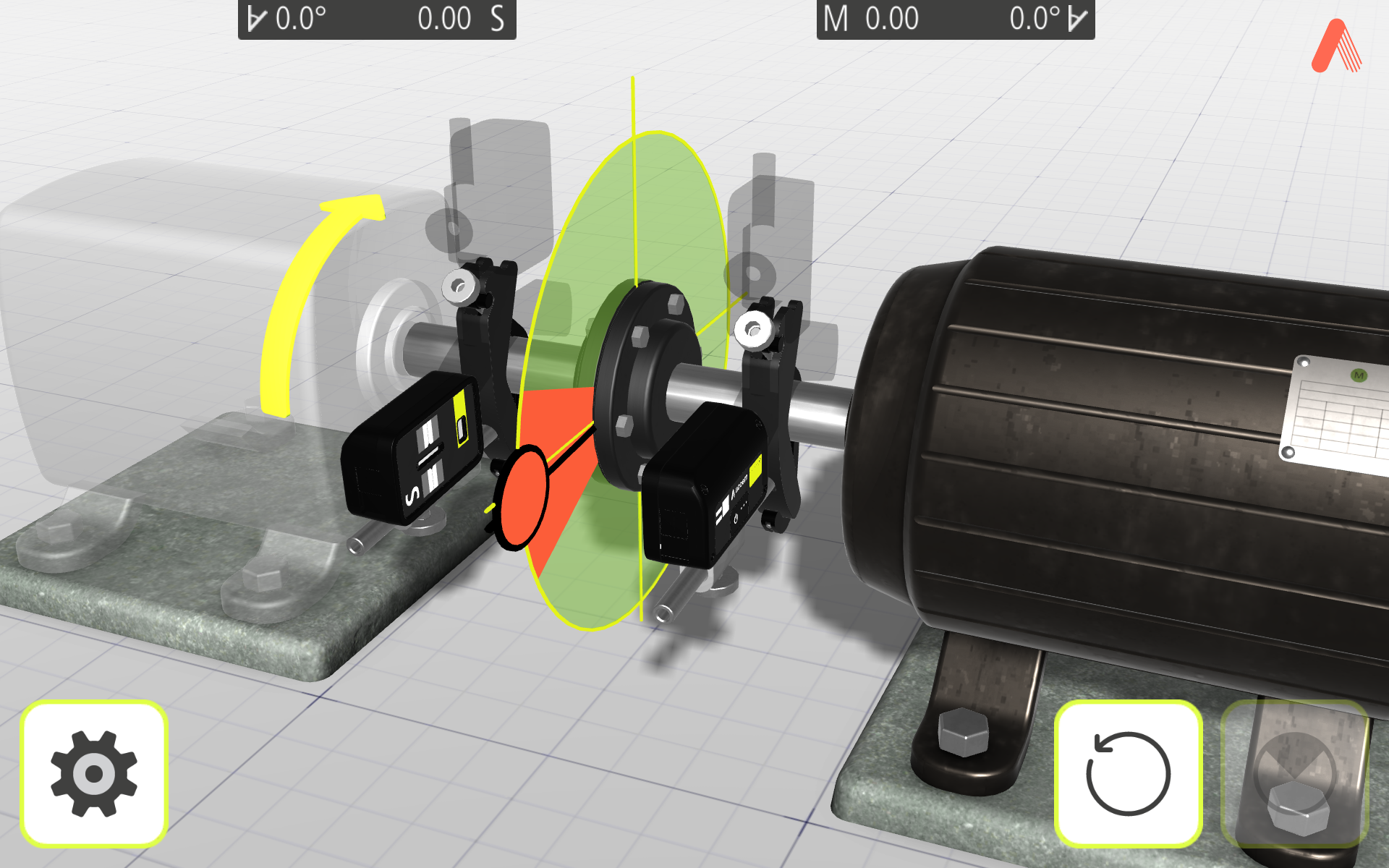

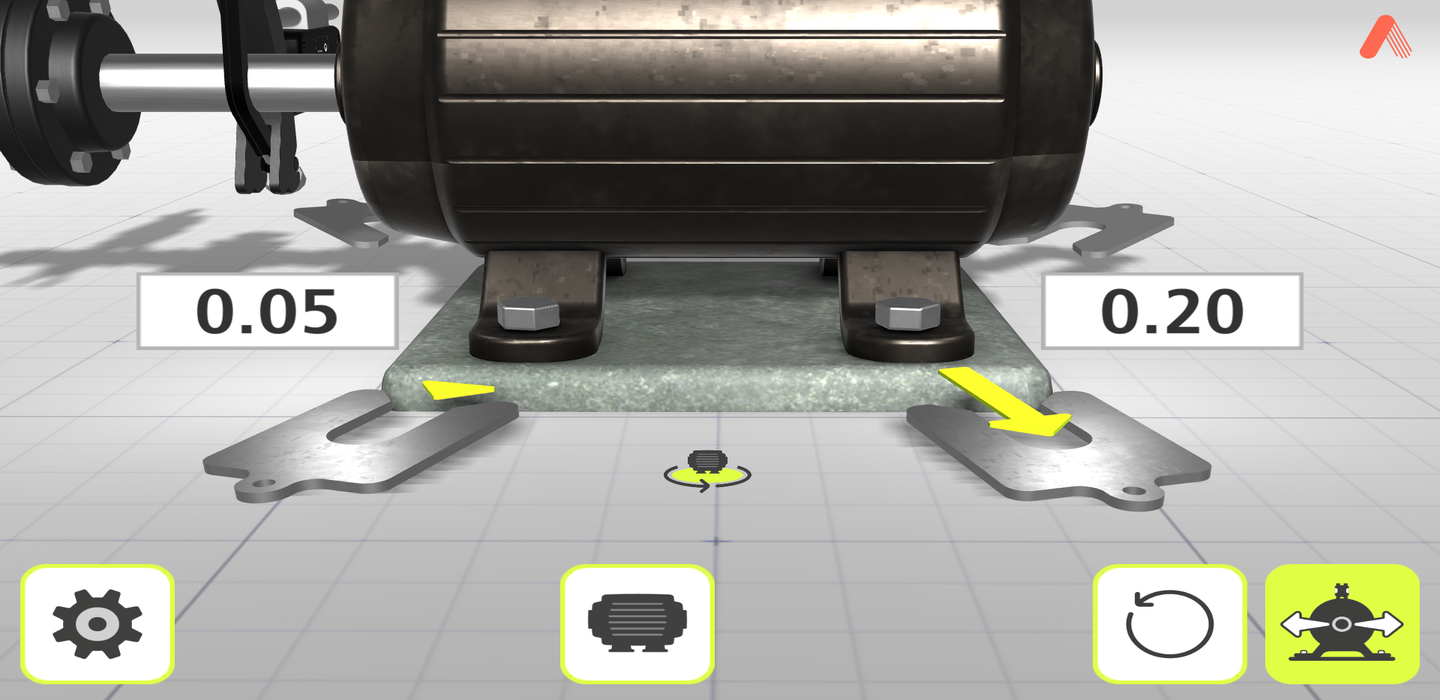

AT-100 is an app-based alignment tool that combines integrated apps, patented technology, and easy connectivity. The AT-100 is suitable for entry-level to expert shaft alignment work, the AT-100 shaft alignment tool provides high measurement flexibility. The intuitive tool works with the shaft alignment apps on a tablet or smartphone. It is simple to use and doesn’t require any special training. The AT-100 shaft alignment solution is the result of almost 40 years of shaft alignment expertise and innovation, leveraging the latest technology to enhance your user experience.