Why condition monitoring is critical for cement plants?

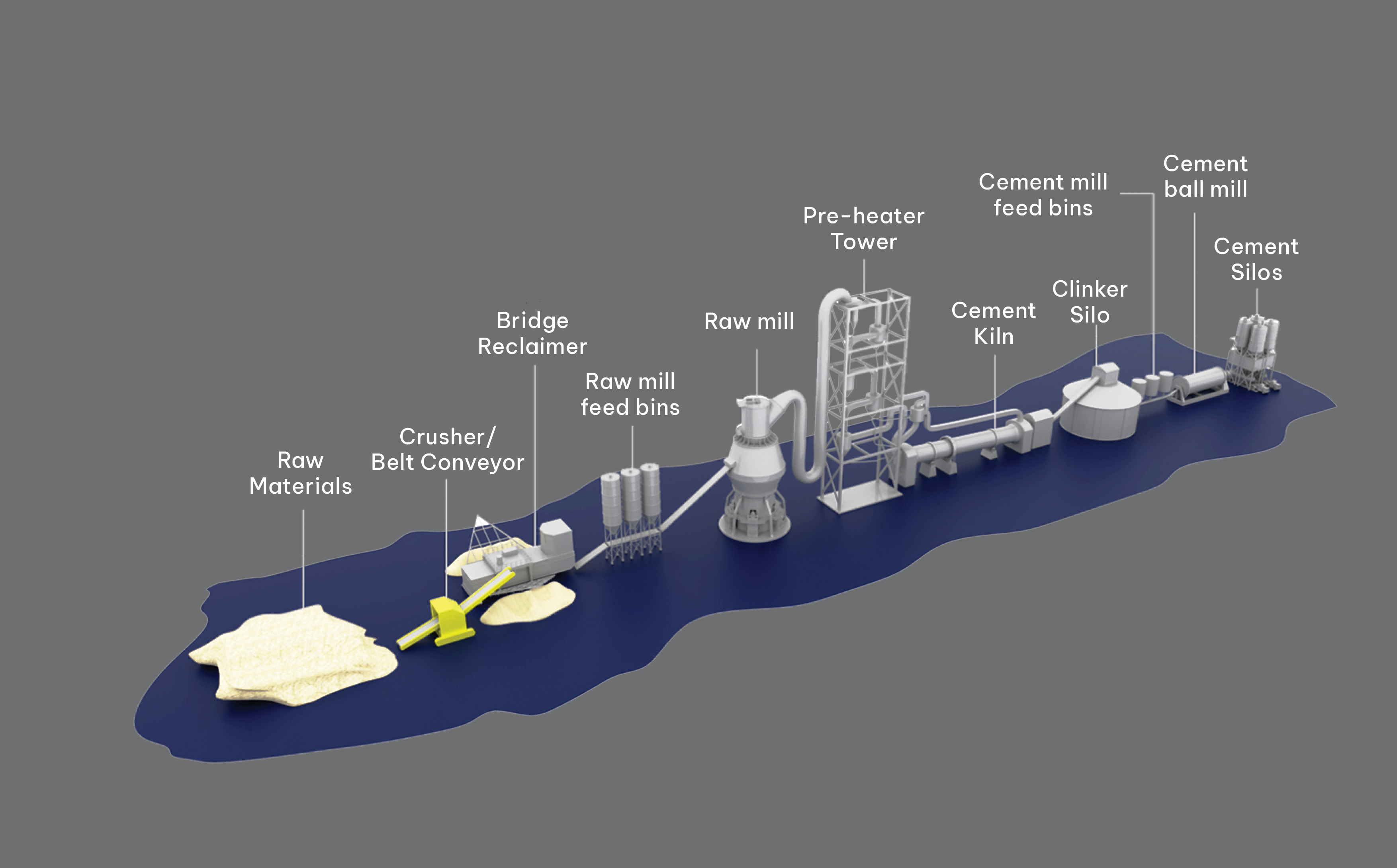

Making cement involves complicated processes that require different types of equipment. Cement plants have important assets like crushers, mills, kilns, and conveyors that need to keep working nonstop to maintain productivity. But if any of these assets fail, it can lead to unplanned downtime. This can result in big financial losses and reduce the amount of cement a plant can produce.

Challenges for Condition Monitoring in Cement Plants

- Complex process with many machines & steps

- Chances of Industrial hazards

- Difficult Remote & Monitoring Control

- Loss from sudden machine failure & downtime

- Wear & tear of assets from overuse

- Huge repair & spare part costs

- Harsh & dynamic operating environment

The industry is changing how it maintains equipment. Instead of sticking to a fixed schedule, they now use technology to predict possible issues. By constantly monitoring equipment conditions, they can identify and fix problems before they become serious.

This new approach, called reliability-centered maintenance (RCM), aims to give early warnings of trouble. The goal is to prevent sudden equipment failure by addressing issues in advance. Predictive maintenance is becoming popular in the manufacturing industry, and condition monitoring using techniques like vibration and oil analysis is helping to improve equipment availability.

Common Causes of Machine Downtime in a Cement Plant

In a cement plant, the smooth operation of machines is essential for maintaining productivity and meeting production targets. Unfortunately, there are several common causes that can lead to machine downtime and disrupt the plant’s operations. In this blog post, we will explore these common causes of machine downtime in a cement plant and understand why they occur.

Various Industrial Fans:

Industrial fans play a crucial role in the cement production process, assisting in material transportation and cooling. However, issues such as motor failure, bearing problems, or belt misalignment can cause these fans to malfunction, resulting in machine downtime.

Double Facer Drum:

The double facer drum is an important component in the production of cement. It is responsible for the bonding process of materials. If the drum encounters issues like mechanical failures or misalignment, it can lead to machine downtime and affect the production flow.

Conveyor Pulley Bearings:

Conveyor systems are vital for transporting materials within the cement plant. The bearings in conveyor pulleys are subjected to continuous stress and wear. When these bearings become faulty or fail due to lack of lubrication or excessive load, it can disrupt the conveyor system and halt operations.

Shaft Impeller:

The shaft impeller is responsible for the efficient movement of air and gases in the cement plant. Problems such as imbalance, misalignment, or damage to the impeller can impact its performance, leading to machine downtime and affecting the overall process.

Suction Vacuum:

Suction vacuum systems are used in various stages of cement production for material handling and dust control. When there are issues with the vacuum system, such as clogged filters or malfunctioning valves, it can hinder the smooth operation of equipment and result in downtime.

Kiln-Feed Pumps:

Kiln-feed pumps are critical for supplying raw materials to the kiln. If these pumps encounter problems like motor failure, seal leakage, or impeller damage, it can disrupt the material flow, leading to machine downtime and affecting the kiln operation.

Gearboxes:

Gearboxes are essential for transmitting power and ensuring the proper functioning of various machines in the cement plant. Gearbox failures caused by issues like lubrication problems, gear wear, or misalignment can lead to sudden machine stoppages and production delays.

DCP (Distributed Control System):

The Distributed Control System (DCP) is responsible for monitoring and controlling the plant’s processes. DCP malfunctions or software glitches can disrupt the control and automation systems, resulting in machine downtime and impacting the overall plant operations.

Roller Press:

The roller press is used for grinding raw materials in the cement manufacturing process. If the roller press experiences issues such as bearing failures, hydraulic problems, or excessive vibrations, it can lead to machine downtime and affect the grinding operation.

Rotary Feed:

The rotary feed mechanism supplies materials to different sections of the cement plant. When issues like mechanical failures, jamming, or material blockages occur, it can disrupt the material flow, causing machine downtime and affecting production.

Hammer Crusher:

Hammer crushers are used for crushing raw materials in the cement production process. If these crushers face problems like excessive wear, misalignment, or hammer breakage, it can result in machine downtime and affect the crushing operation.

Corrugated Slag Mill:

The corrugated slag mill is responsible for grinding and processing slag materials. Faults such as liner wear, motor malfunctions, or jamming can impact the mill’s performance, leading to machine downtime and affecting the slag grinding process.

Head Sprocket Pumps:

Head sprocket pumps are crucial for pumping fluids within the cement plant. If these pumps encounter issues such as motor failures, seal leaks, or impeller damage, it can disrupt the fluid flow and cause machine downtime.

Separator Motors:

Separator motors are used in cement plants to separate fine particles from the finished product. When these motors experience faults like electrical failures or bearing issues, it can lead to machine downtime and affect the separation process.

Mill Elevator:

The mill elevator is responsible for transporting materials within the cement mill. Problems like mechanical failures, belt misalignment, or excessive wear can impact the elevator’s performance, leading to machine downtime and affecting the material transportation process.

Machine downtime is a significant challenge faced by cement plants, and understanding the common causes is crucial for effective maintenance and minimizing disruptions. By addressing these issues promptly through proactive maintenance and regular inspections, cement plants can optimize their operations, reduce downtime, and enhance productivity, ultimately ensuring smooth and efficient production processes.

Acoem Reliability Services

Tailored for the Cement Industry

Acoem has developed a tailored approach to address the reliability challenges faced by the cement industry. By conducting thorough audits, predicting equipment failures, and implementing sustainable solutions with advanced technologies, Acoem helps cement plants improve their operations.

The main goal of Acoem is to identify cost-effective and practical maintenance techniques that minimize the risk and impact of equipment failure on facilities and utilities. By doing so, they ensure that systems and equipment function optimally in the most economical way.

In particular, Acoem’s Reliability strategy for the cement industry focuses on the following objectives:

Maximizing Cost-Effectiveness: Acoem aims to identify maintenance techniques that provide the best value for money, allowing cement plants to reduce maintenance costs without compromising reliability.

Minimizing Risks and Impact: By assessing potential failure risks and their impact on operations, Acoem helps cement plants implement preventive measures to minimize downtime and operational disruptions.

Enhancing Equipment Functionality: Acoem focuses on maintaining the functionality of systems and equipment in the most efficient and sustainable manner, ensuring longer equipment lifespan and improved operational efficiency.

By adopting Acoem’s reliability strategy, cement plants can achieve reduced maintenance costs, prolong the lifespan of their equipment, and enhance overall operational efficiency. Acoem’s tailored solutions help address the unique reliability challenges faced by the cement industry, leading to improved performance and customer satisfaction.

Our expert team has years of experience working on different cement technologies with

exposure to local industrial working conditions. This specialist knowledge combined

with many years of experience has led us to offer comprehensive monitoring and

diagnostic services remotely as well as on-site.

Acoem offers a range of reliable services designed to support the smooth operation of cement plants. These services include:

Health Assessment of Critical Assets:

Thorough health assessments of vital equipment in cement plants such as Roller Presses, Kiln Main Drives, and Vertical Roller Mills. This helps identify any issues or potential failures, enabling proactive maintenance to prevent costly downtime.

Precision Maintenance Correction:

Precision maintenance correction, including tasks like torsion shaft alignment of Rotary Kilns, Ball Mills, and Cooling Towers. By ensuring precise alignment, they optimize the performance and longevity of these crucial components.

In-Situ Dynamic Balancing:

Helping to eliminate any imbalance in the fans, leading to smoother and more efficient operation while reducing wear and tear.

Advanced Engineering Services:

Advanced engineering services for troubleshooting rotating machinery in cement plants. They offer expertise in diagnosing and resolving issues with equipment to minimize downtime and maximize productivity.

False Air Leakage Detection:

Detecting false air leakages in cement plants. By identifying and sealing these leaks, they help improve energy efficiency and optimize the overall performance of the plant.

Compressed Air and Gas Leak Detection:

Detection of compressed air and gas leaks in cement plants. Addressing these leaks not only saves energy but also improves safety and reduces operational costs.

Localizing Partial and Corona Discharge:

Localizing partial and corona discharge in switchyards and switchgears. By identifying these electrical issues, they help prevent potential equipment failures and ensure a reliable and secure power supply.

Acoem’s reliable services cater to the specific needs of cement plants, enhancing their efficiency, reliability, and overall performance. By leveraging their expertise, cement plants can minimize downtime, improve energy efficiency, and optimize the functionality of their critical assets.

Next Generation Reliability Solutions

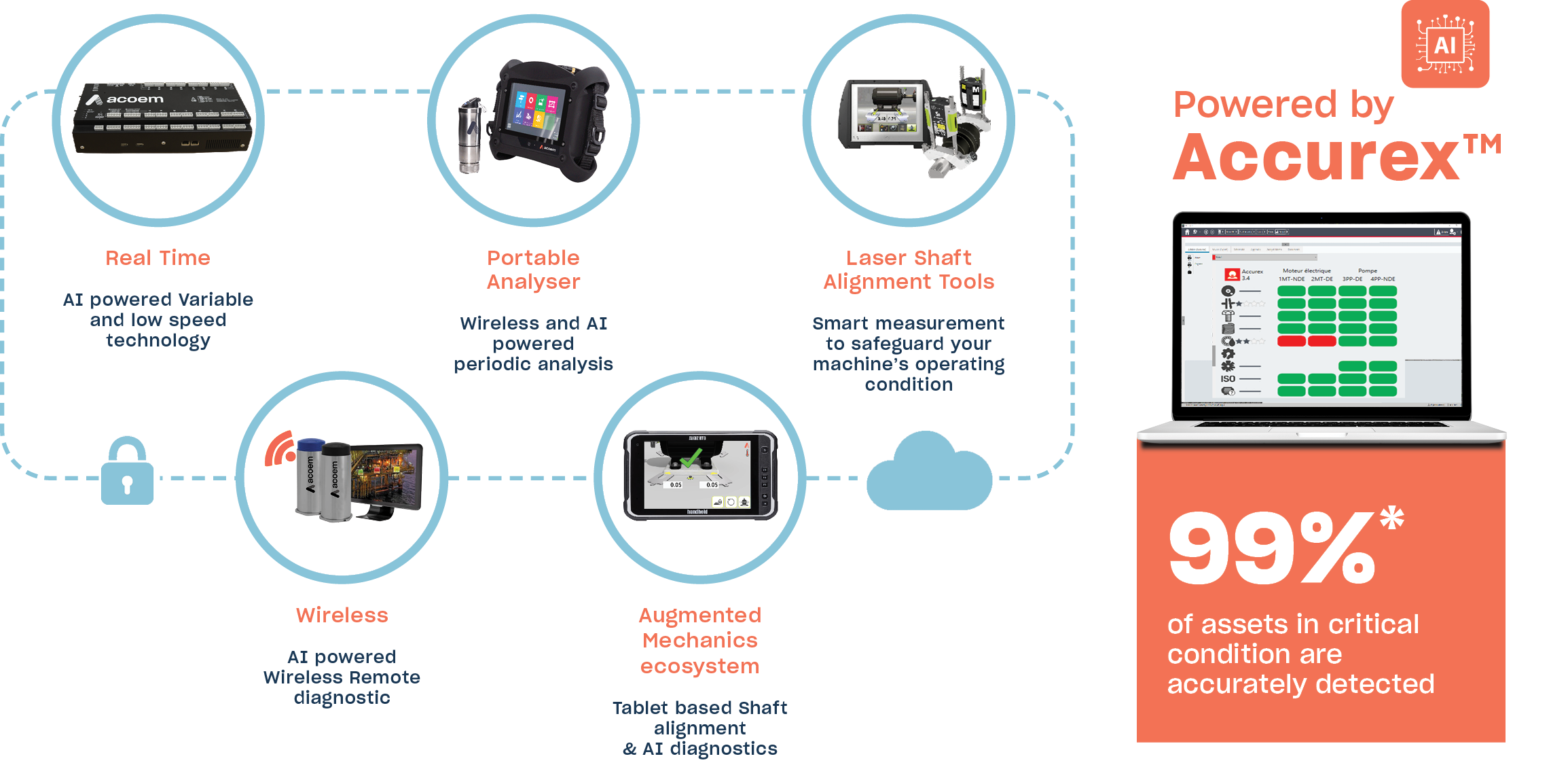

A suite of IOT-driven ecosystem

Our predictive maintenance tools, powered by AI and utilizing wired or wireless sensors, IoT, augmented mechanics, machine learning, and data analytics, help anticipate problems before they occur. Schedule maintenance at the right time, receive alerts for potential issues, and enhance industrial productivity with certainty.

Connect with Acoem

Find out how our reliability services can greatly improve the reliability of your plant operations. Our reliability strategy seamlessly integrates with your maintenance strategy, ensuring increased asset integrity and availability.

Explore our comprehensive solutions, services, and training programs to learn more about how we can support your organization in achieving plant reliability. We provide a range of tailored services designed to optimize your assets and enhance operational efficiency.

Don’t miss out on the opportunity to enhance your plant’s reliability. Get in touch with us today to find out more about our reliability services and how they can benefit your organization.