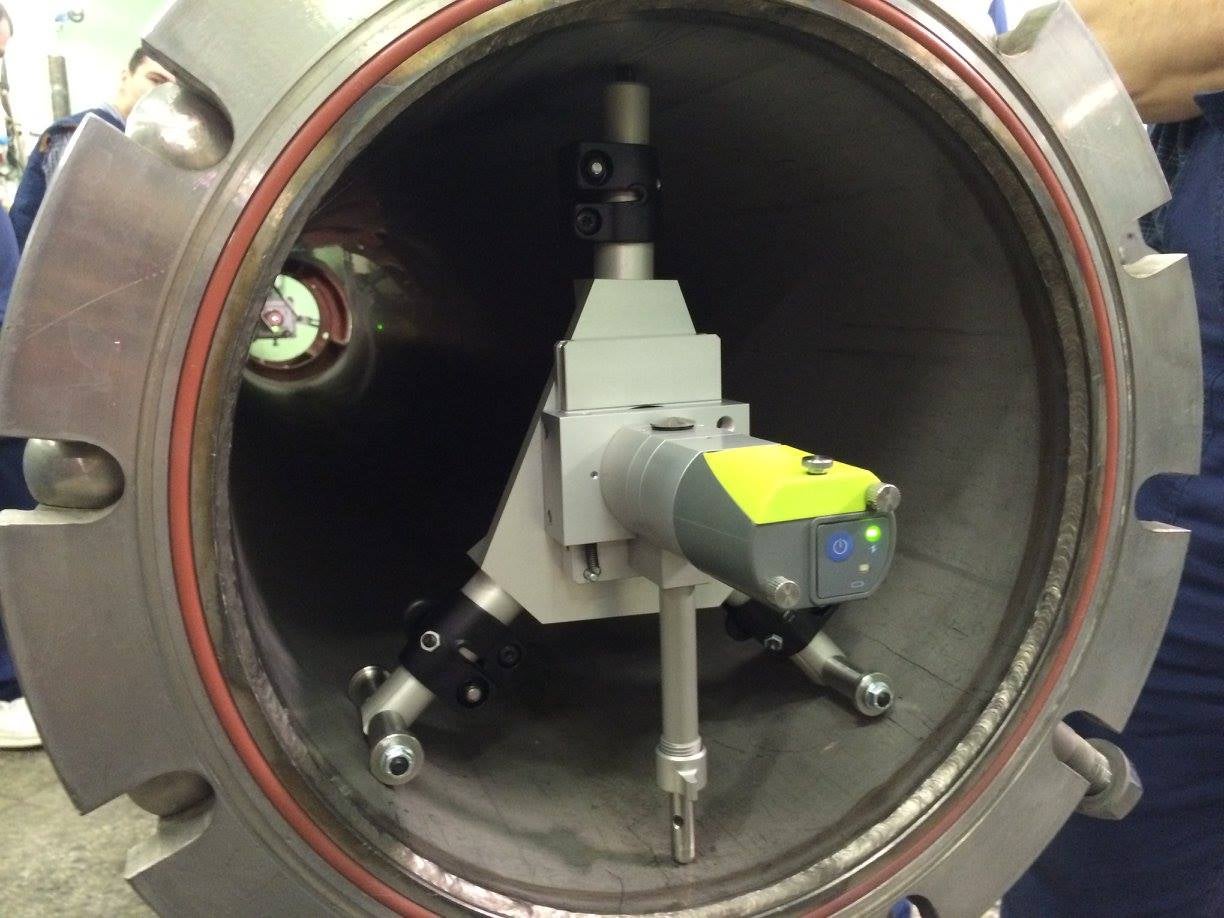

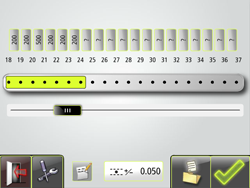

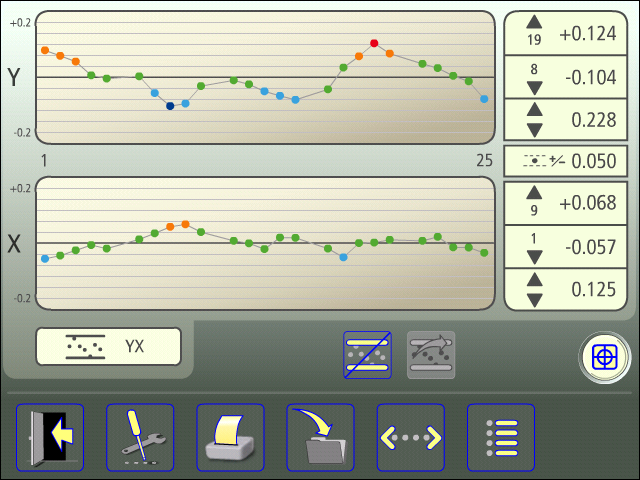

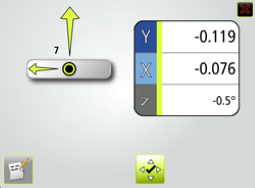

Bore measurements

Halfbore or fullbore – no bore for our instruments

Typical applications are full bore measurements, e.g. bearing journals for compressors and in diesel engines.

Typical applications are full bore measurements, e.g. bearing journals for compressors and in diesel engines.

Contact us to learn more about our solutions, services, and training programs.