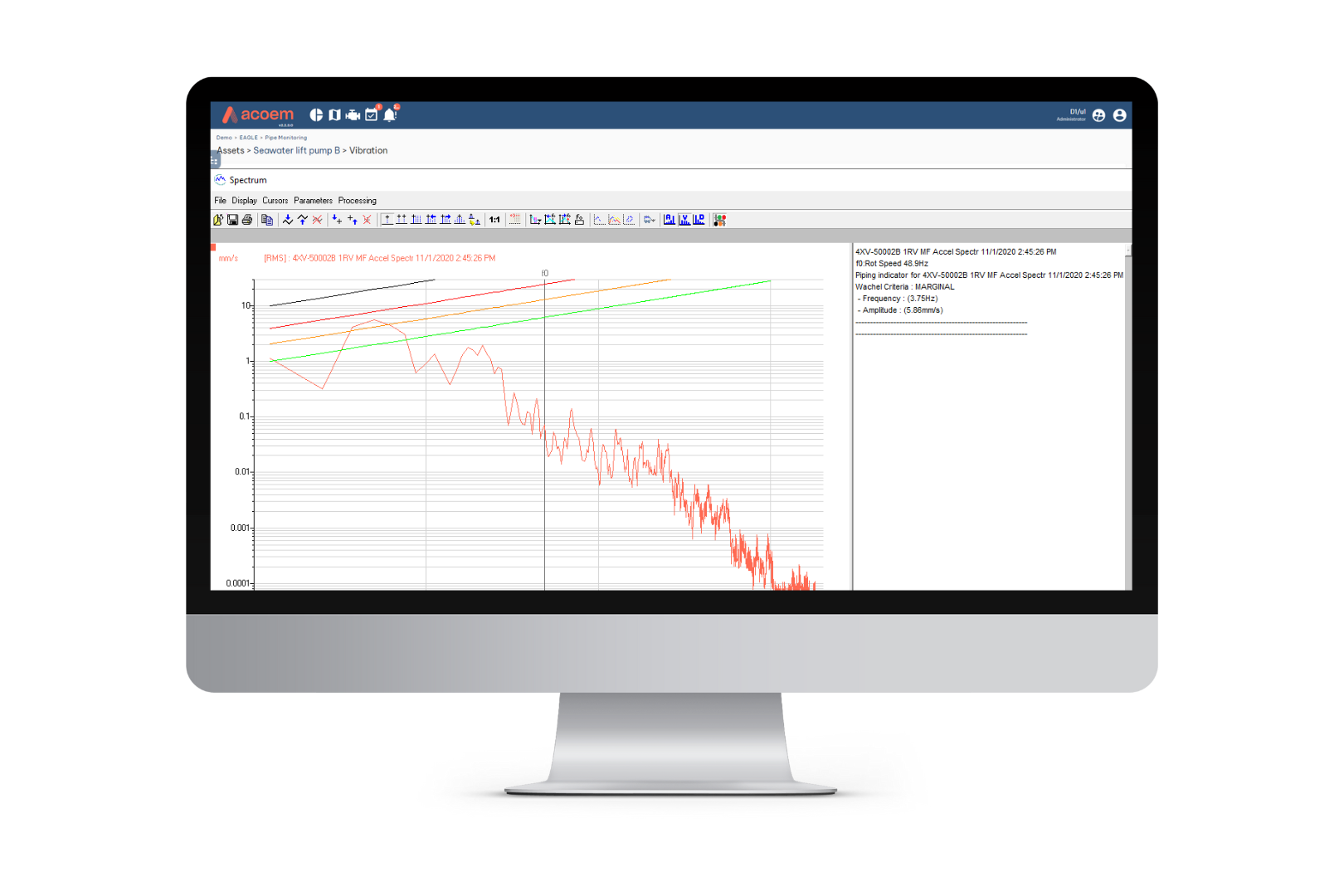

Introducing the latest addition to the Nesti4.0 software platform – the Acoem Piping module – designed specifically for piping monitoring

With an ever-growing demand for energy, especially in the current global geo-political situation, the Oil and Gas industry is continually under pressure to increase production. But to boost flow rate safely and efficiently, accurate monitoring of piping vibration is required to avoid potential hazards like cracking in the piping, overheating or larger critical failures which may have catastrophic consequences.

Until now, the process of monitoring critical pipes has been costly, labour intensive and could only provide measurements for a particular point in time – making the data unreliable for decision making.

As production parameters change – such as temperature, flow rates, gas composition, basic sediment & water (BSW), pressure – so too do vibration levels, making accuracy almost impossible.

Precise and ongoing vibration monitoring is mandated by standards that apply across on-shore and off-shore production facilities worldwide, including set guidelines for the avoidance of vibration-induced fatigue or failure in pipework.