Acoem has developed a new shaft alignment tool, EVO, which features our unique adaptive user interface. The tool’s simplicity in its handling is characteristic for all Acoem tools; an alignment tool that can be handled by all maintenance professionals, and not only experts.

Few features in the shaft alignment world are as innovative and time saving as the VertiZontal Moves. Its adaptive interface shows how much a misaligned machine requires for the vertical move by adding or removing shims at the machine’s feet. Proceeding with the measurement, it requires no remeasurements in between vertical and horizontal adjustment during the alignment process. The horizontal adjustment is promptly carried out with real values displayed during the entire process.

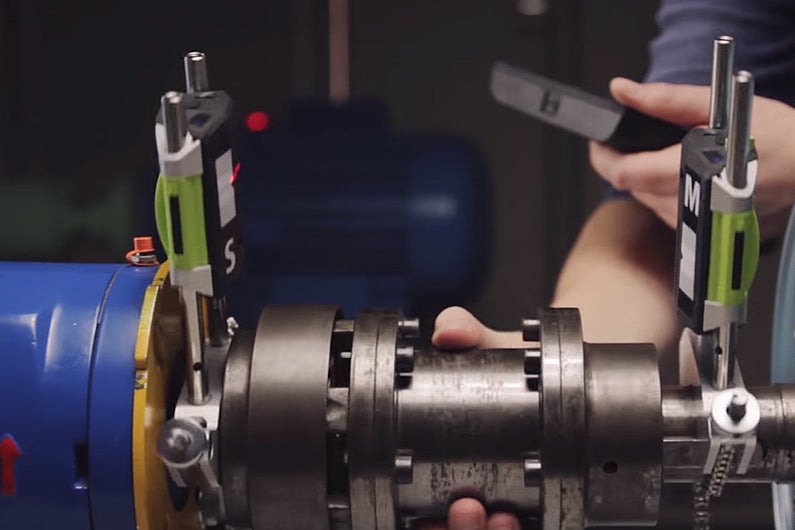

The EVO is an all-digital shaft alignment tool with wireless, built in Bluetooth in the sensor units. The units are also fitted with a 30 mm CCD detector that gives the user an unparalleled measurement accuracy and precision.

The EVO offers a compact display unit with a 5” color touch screen. It is slim and balanced, allowing you to hold it in one hand, leaving your other hand free to touch the screen icons and rotate the sensors on the shafts.

“We do not dare to claim that we match Albert Einstein’s genius, as we quote him: “Everything should be made as simple as possible, but not simpler.” says Hans Svensson, CEO of Elos Fixturlaser AB. “We will, however, claim to be the most innovative in our efforts to make the life of maintenance professionals as problem-free as possible.”

For further information about the Acoem EVO system and technical details, please contact us.