A customer called me, extremely frustrated, because he could not get a good alignment. “I’ve spent two hours trying to align this pump!” he said. He blamed the laser alignment equipment, the pump, the bad base, bad maintenance, and everything else that came to his mind.

I did not take it personally, because I’ve been there too! I listened to his frustrations, and let him vent. And after a few minutes, I interrupted the “venting”, and said, “If you’ll give me two minutes, I’ll tell you how you can fix it.”

The secret – start all over again, and follow the steps.

- Take out all of the shims, clean up the feet and the base a little bit more

- Rough the alignment in-just get it “eyeball” close.

- Get rid of soft foot. Start with the worst foot, and work your way down. Don’t concentrate on making soft foot perfect-just make it better.

- Tighten the motor and hold down bolts in the same order, each time.

- Do what the laser system says to do.

I received an email from him the next day, thanking me for my help, and letting me know achieving alignment was fast, simple, and repeatable.

Alignment frustration isn’t new, but it is treatable by the right approach.

It’s easy to take a short cut, put in an incorrect shim, or an incorrect value in the laser. And when you do, you’ll end up frustrated, just like this guy did.

Step away.Take a short break, if possible.. Get your mind off the alignment for just a few minutes. Then start all over, and don’t skip any steps.

The cure for alignment frustration is ALWAYS a good alignment approach and practice!

Shaft Alignment Frustration!

The most common reasons for alignment frustration are:

- Not truly understanding what precision shaft alignment is.

- Not knowing how the alignment tool works.

- Improper set-up.

- Not taking care of the basics:

- Roughing in before mounting the sensors.

- Checking brackets, bolts, rods, heads, etc. for looseness.

- Minimizing soft foot

- Tightening the hold down bolts in a controlled method.

- Controlling backlash.

- Using damaged shims or using something that is not precise enough to be called a shim.

- Getting in a hurry, instead of working fast and efficiently.

- Not having, or using, jacking bolts to precisely control horizontal movement.

Believe me, I have done most of these at some time in my life, so I can relate.

Machinery and equipment with moving parts rely on mechanical alignment between these moving parts to run smoothly and efficiently. Often, machinery alignment is checked, deemed OK for manufacturing, and then forgotten — at least until some event catches the attention of plant engineers. These events might be a slight decrease in production output, an unfamiliar noise or squeak, or some dramatic event such as black smoke pouring from a motor housing or grinding gears.

Before laser alignment, mechanical systems were typically aligned using optical transits or piano wire pulled between two ends of a machine.

Plant personnel know the frustration of trying to make precise alignments with a ruler and a piece of sagging wire swinging in the breeze. In the past, the tools available for accurate alignment have been limited and technically challenging to use.

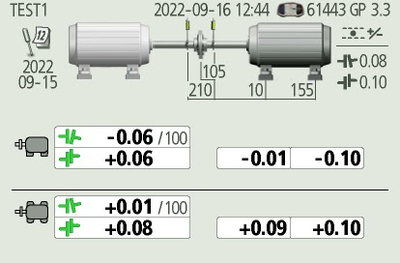

Laser alignment provides a highly precise and efficient means of checking machinery.

These products are easy and simple to use by plant or production personnel on the factory floor.

Much of the guesswork and subjectivity of traditional alignment techniques is eliminated because the laser now delivers precise, quantitative data, and in some instances, complete instructions on how to correct machinery flaws. Consequently, lasers are finding their way into many industrial plants.

Do you get frustrated when aligning machinery?

Have you developed your own “shortcuts” that sometimes work, and sometimes don’t?

Do share with us your frustrations and we will be happy to align with you

Connect with Acoem

Get more information about vibration monitoring and how it can help you achieve plant reliability. Find out more about our comprehensive solutions, services, and training programs.