Beating vibration impact on a pumping station

At a pumping station, operators observed strong vibrations affecting both the machinery and the building structure. Initially, they suspected that the pump and the building’s foundation were responsible. The issue appeared to be linked to the pump’s operating conditions and occurred only when it was running at high output levels.

Visualising vibration data using time-domain patterns and frequency spectra

Vibration analysis identified several factors contributing to the problem:

Pumping Station Layout

The station operated three centrifugal pumps at different speeds. Pumps 2 and 3 exhibited high vibration levels when running at high output, particularly at the first order (rotational frequency) in the vibration spectrum. Beating effects were also detected in the building vibrations.

Diagnostic findings

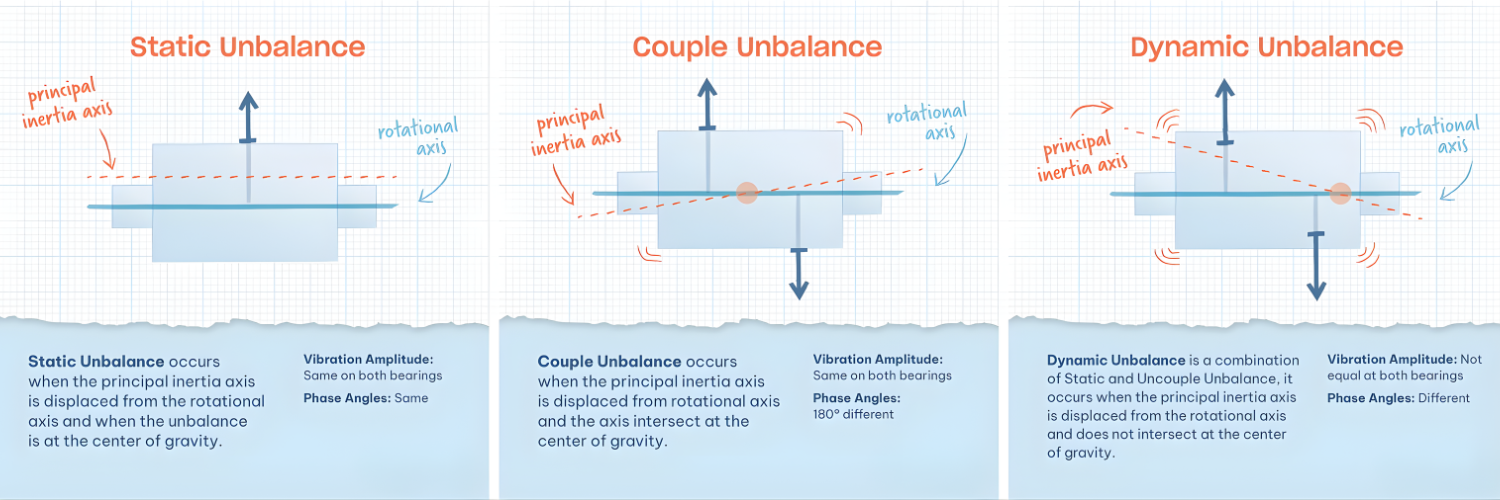

Unbalance

The analysis showed significant rotational vibrations as the motor speed increased. Upon inspection, issues were found with the coupling keys—some were protruding, while others were missing altogether.

Critical speed

The motor’s natural frequencies fell within its operating speed range. As a result, when passing through a bending critical speed of around 3600 rpm, there was a marked increase in vibration amplitudes.

Solutions and recommendations

Coupling correction

The problems with the coupling keys were rectified.

Precision balancing

The motor was precision balanced, significantly reducing vibration amplitudes and eliminating the beating effect within the building. However, some beating persisted at the critical speed, making continuous operation at that speed inadvisable.

Motor replacement

It was advised to either carry out an extensive system rebuild or replace the motor with one whose natural frequencies do not fall within the operating speed range. New pump motors should comply with international standards, such as EN ISO 13709, which provides mechanical vibration guidelines for rotating and reciprocating machinery.

By identifying and addressing the root causes of the vibration issues, the pumping station can achieve more reliable and efficient operation, reducing the risk of damage and unplanned downtime.