Shaft alignment tools

Acoem shaft alignment tools

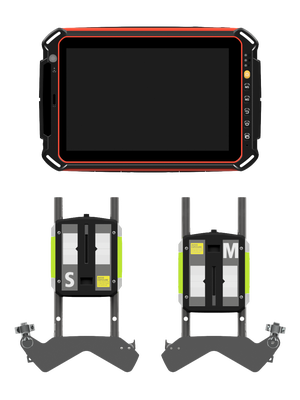

Connected shaft alignment tools and systems

Acoem’s connected shaft alignment tools are cloud-enabled and connect with our Bluetooth laser alignment sensors.

We offer a range of precision laser shaft alignment tools and packages to suit a variety of applications, budgets and expertise, from simple entry level, no frills devices to augmented mechanics Cloud-based connected systems.

Classic Shaft Alignment Tools Systems

Acoem’s classic shaft alignment systems feature a proprietary display unit that connects with our bluetooth laser alignment sensors.

We offer a range of precision laser shaft alignment tools and packages to suit a variety of applications, budgets and expertise, from simple entry level, no frills devices to augmented mechanics Cloud-based connected systems.

Shaft Alignment Accessories

Simple, easy operation with advanced features and capabilities, including geometric measurements. The ultimate in shaft alignment tools.

Offset

Machines with offset drives are often thought of as insensitive to angular errors between driving and driven shaft.

Applications that benefit from Acoem laser shaft alignment tools

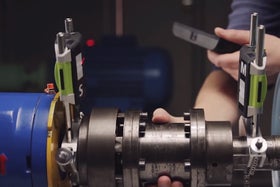

See it in action

Learn more or schedule a demo.