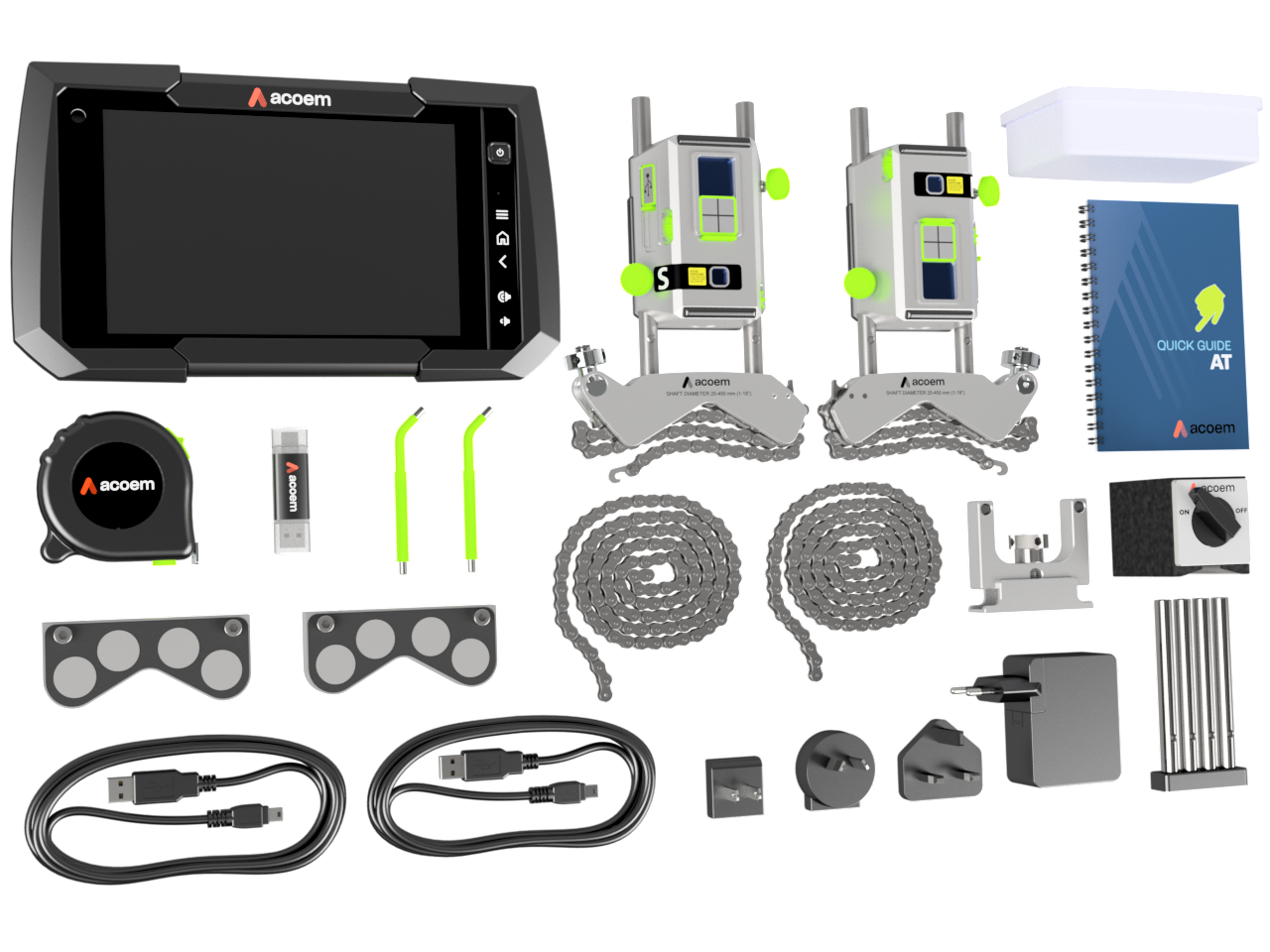

AT-400

Achieve precision with the Acoem AT-400 high-end dual-axis shaft alignment system.

Its Dual Sweep method captures accurate measurements during shaft rotation, ensuring optimal alignment. Benefit from Dual Multipoint for diverse scenarios, capturing multiple points for precise calculations. Cloud connectivity streamlines report sharing, while the lifetime warranty underscores its reliability.

Trust the Acoem AT-400 for robust dual-axis sensors and unparalleled versatility. Explore various measurement programs for horizontal, vertical, flatness, and soft foot conditions.