Piping monitoring solution

Detect, locate and classify threats in real time

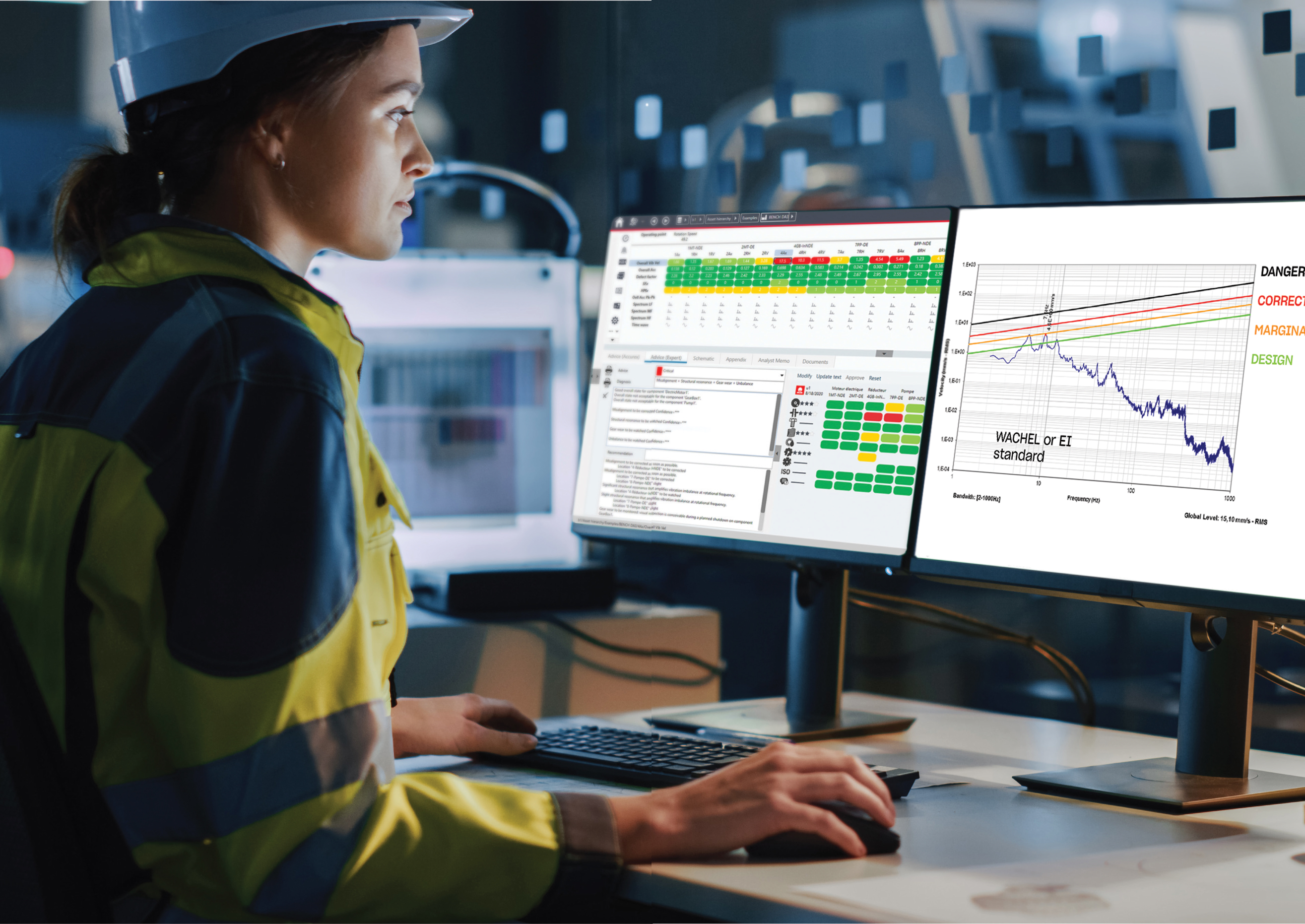

The combination of safety standards and smart IoT sensor technology

Tailored to the particular type of energy being produced and the dimensions of the piping itself, the Acoem Piping module leverages specific algorithms specified by applicable standards to ensure pipe integrity by seamlessly working with the Acoem Falcon, Eagle or MV-x to deliver real-time vibration data with key safety, efficiency, operational and productivity insights.

See it in action

Learn more or schedule a demo.

Would you like to…?