NXA GAMESA

Shaft alignment in the wind power Industry

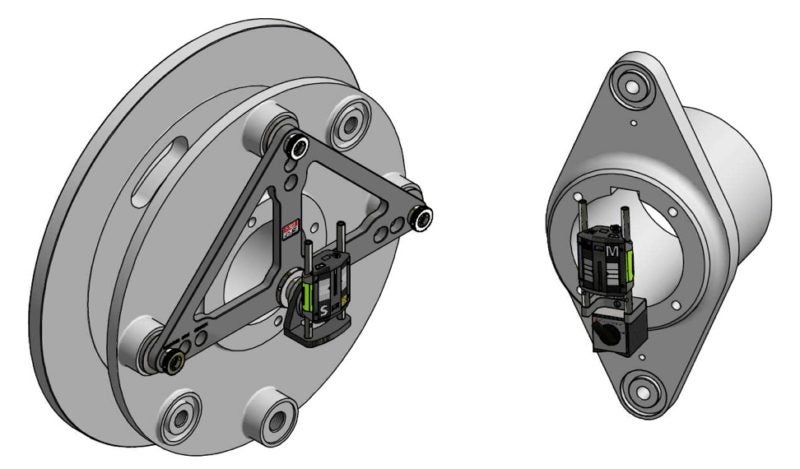

The NXA GAMESA is custom-made with firmware and fixtures designed specifically for Gamesa turbines: G80x, G90x, G114, G126, G132, G145. These precisely designed fixtures make generator-to-gearbox alignment easy inside any nacelle – safeguarding reliability and optimizing the energy efficiency of the wind turbine.