FALCON

Vibration analyzer

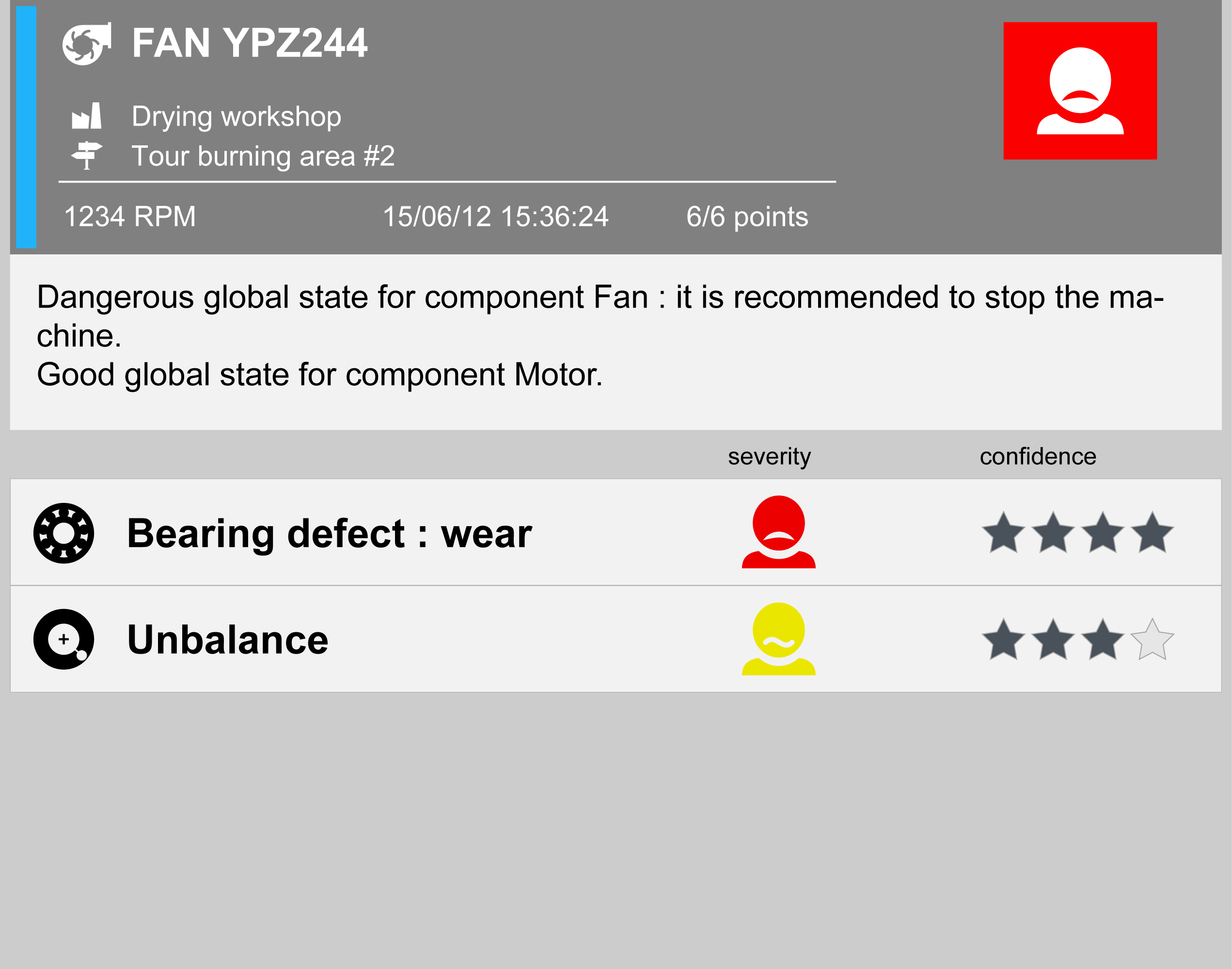

FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

FALCON is an innovative tool for vibration measurement and analysis that puts condition-based maintenance within the grasp of all users.

Discover Acoem’s case studies

With FALCON, Acoem offers a collection, analysis and balancing tool with outstanding performance, accessible to all users.

Acoem has distilled its 30 years of experience with condition-based maintenance into FALCON. Highly experienced and novice users alike can now easily monitor machine vibrations and obtain highly pertinent results.

Contact us to learn more about our solutions, services, and training programs.