There are many tools on the market to use in conjunction with lubrication – mechanic’s stethoscopes, “smart” grease guns which use ultrasonic, or just an ultrasonic tool itself. High frequency vibration measurements can also do this.

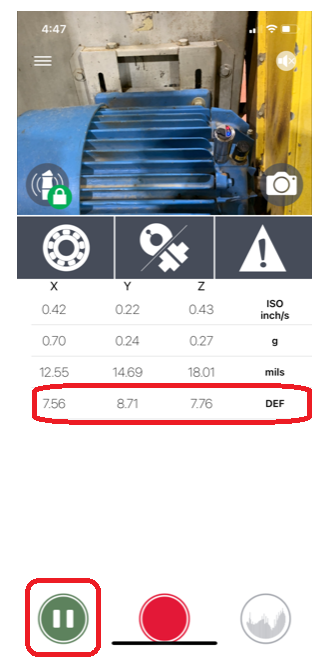

One of the easiest methods to check for lubrication is the Acoem Bearing Defender. In addition to vibration measurements, a Bearing Defect measurement is displayed. The Bearing Defect measurement is a linear scale from 0-12:

- Bearing Defect Number from 0-6 typically indicates a normal bearing signal.

- Numbers from 6-9 may indicate an early stage bearing problem, or a lack of lubrication.

- Numbers above 9 may indicate a damaged bearing. Further analysis is recommended.

In this example, the Bearing Defect Number is 7.56 in the X axis, 8.71 in the Y axis, and 7.76 in the Z axis.

This would indicate a possible problem with the bearing. While data is still being measured, lubricate the bearing one stroke with a grease gun. Wait about 3-5 seconds for the data to average and look for a change. If no change is measured, an additional stroke of grease may be required. Use common sense to determine the number of strokes needed.

If the Bearing Defect number drops, then it is presumed that the bearing is now properly lubricated. Wait 30 minutes or so and recheck. If the number continues to be low, proper bearing lubrication is presumed.

If the number returns to a higher number, or does not change significantly, then it is possible that the bearing has a slight degree of damage. Further analysis should be performed.

The wireless sensor can be moved from bearing to bearing. In this way, a large population of bearings can be checked quickly. Those that need grease can be lubricated, but those that don’t need grease can be skipped, lessening the chance of damaging the bearing by over lubrication.

In the example below the bearing defect values are outlined in red. The values above the bearing defect values are the vibration measurements in velocity, acceleration, and displacement.

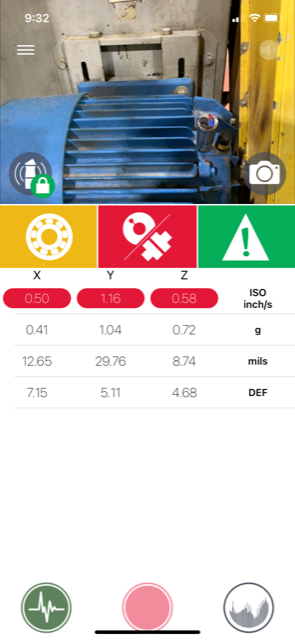

The Bearing Defender app can also be used to perform a quick vibration test of the machine. Choose the red button at the bottom of the screen to collect and analyze vibration data. Collection time is about 10 seconds.

The Bearing Defender uses Accurex© software to determine:

- A bearing fault

- A misalignment or unbalance problem

- Another machine fault not bearings, misalignment, or unbalance

In this example, the bearing fault is yellow (Caution), and the unbalance/misalignment fault is red, indicating the major problem is either unbalance or misalignment. Further analysis would be needed. But first, it would make sense to lubricate the bearing. This would be a simple check to determine if the bearing problem is caused by a lack of lubrication, or by an unbalance/misalignment problem.