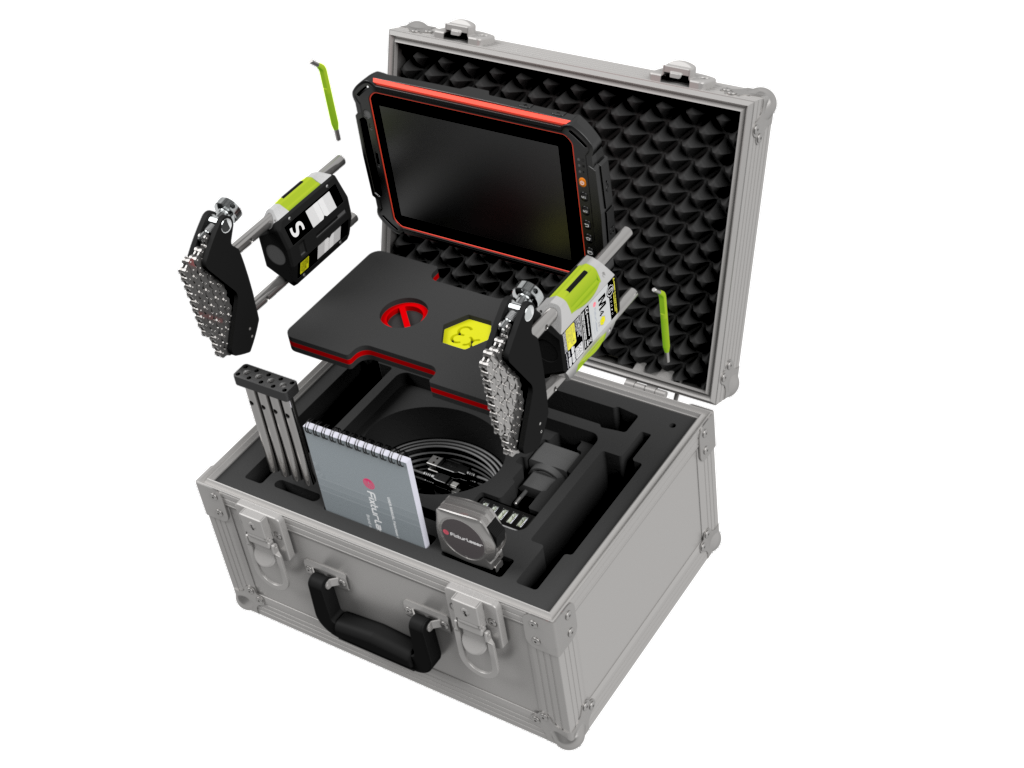

EXO

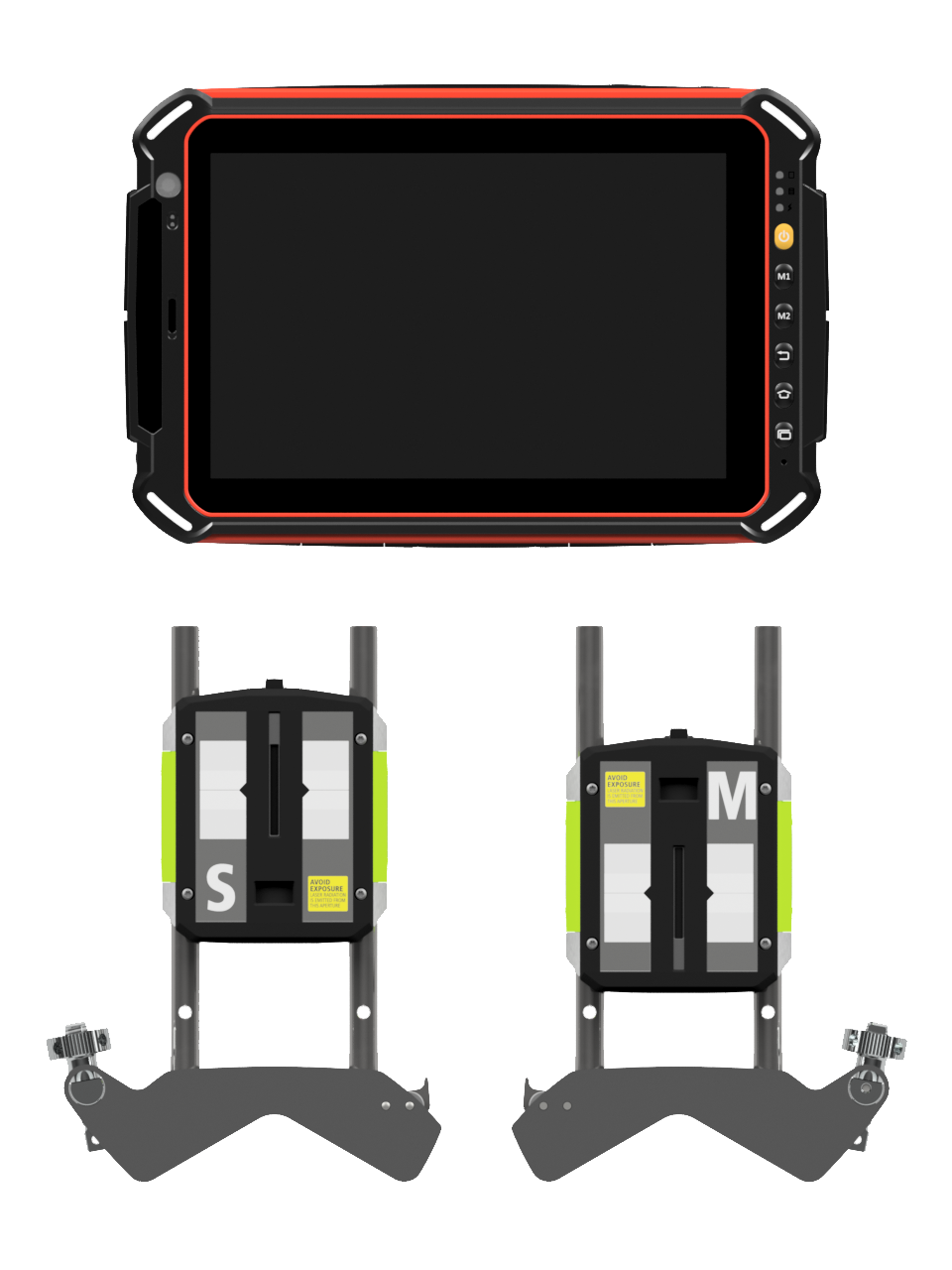

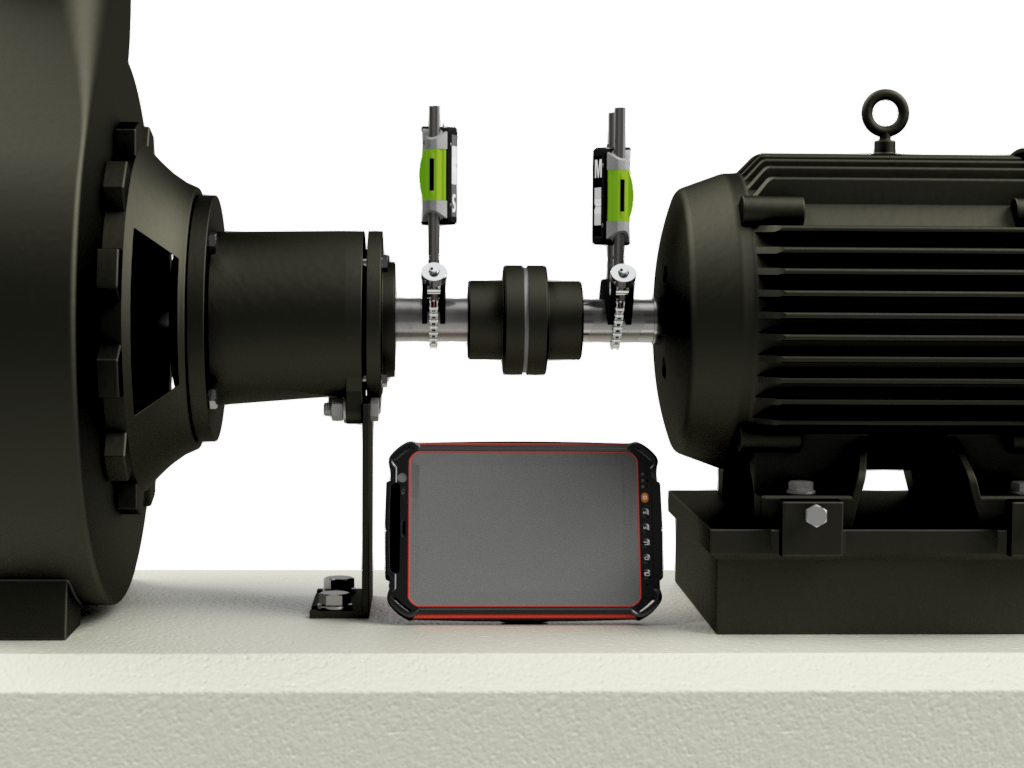

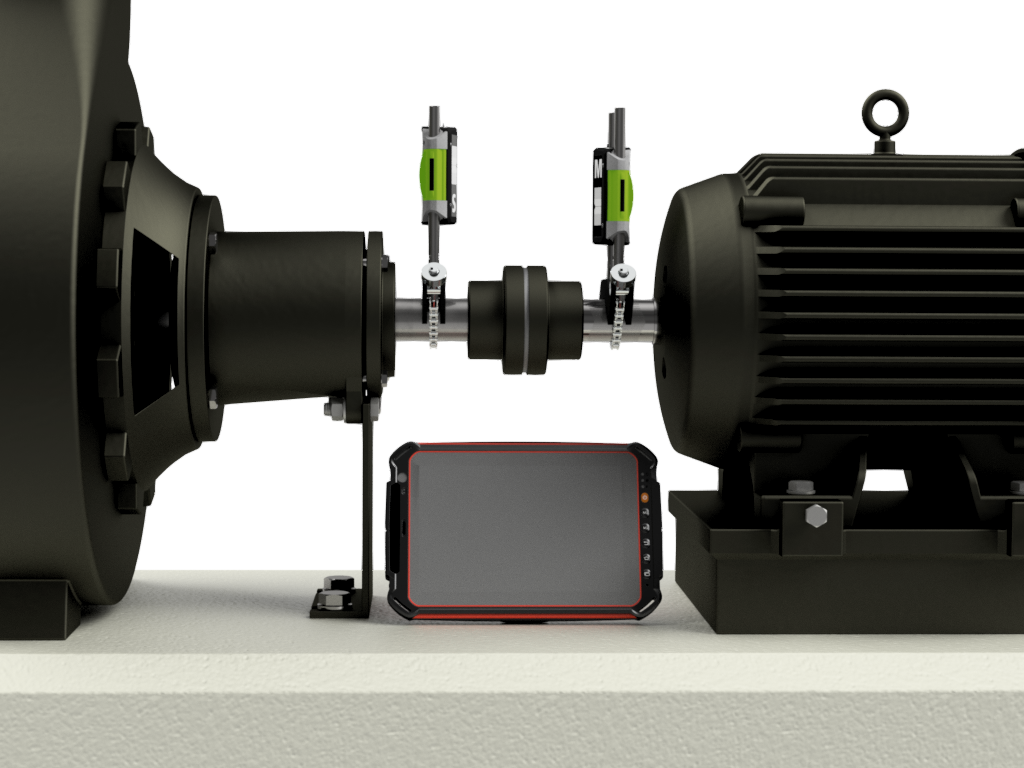

Perform shaft alignments in hazardous areas with the EXO.

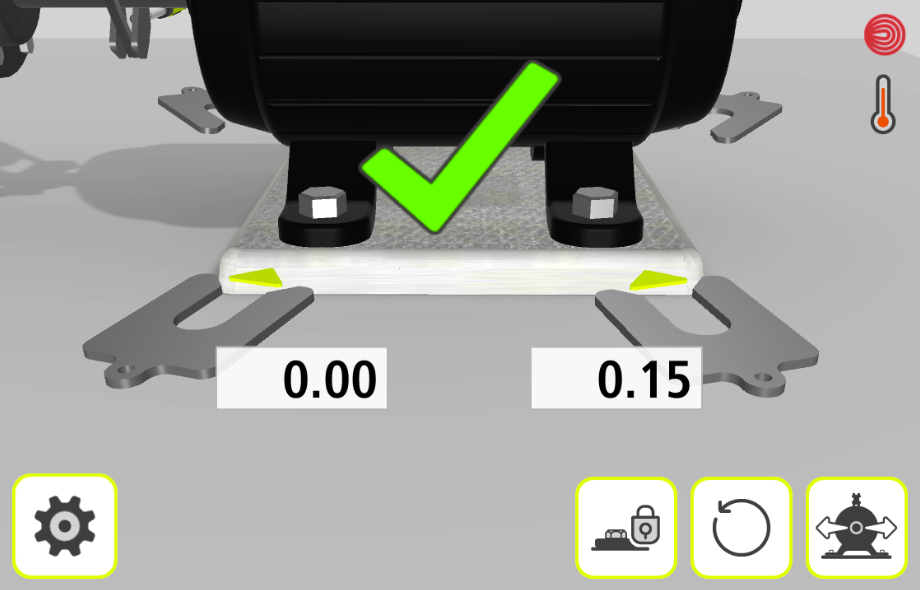

Our core values, GuideU and Alignment Intelligence, have led to the development of several first industry functions, where True Live and VertiZontal Moves™ are unique on the market for laser-based shaft alignment tools. They bring ease of use to our end users, which above all facilitates easy precision shaft alignment, on-the-job time saving, improved reliability, and more importantly, money savings.

With the Acoem EXO, you get all this in an intrinsically safe shaft alignment package.