DSL-460 MkII

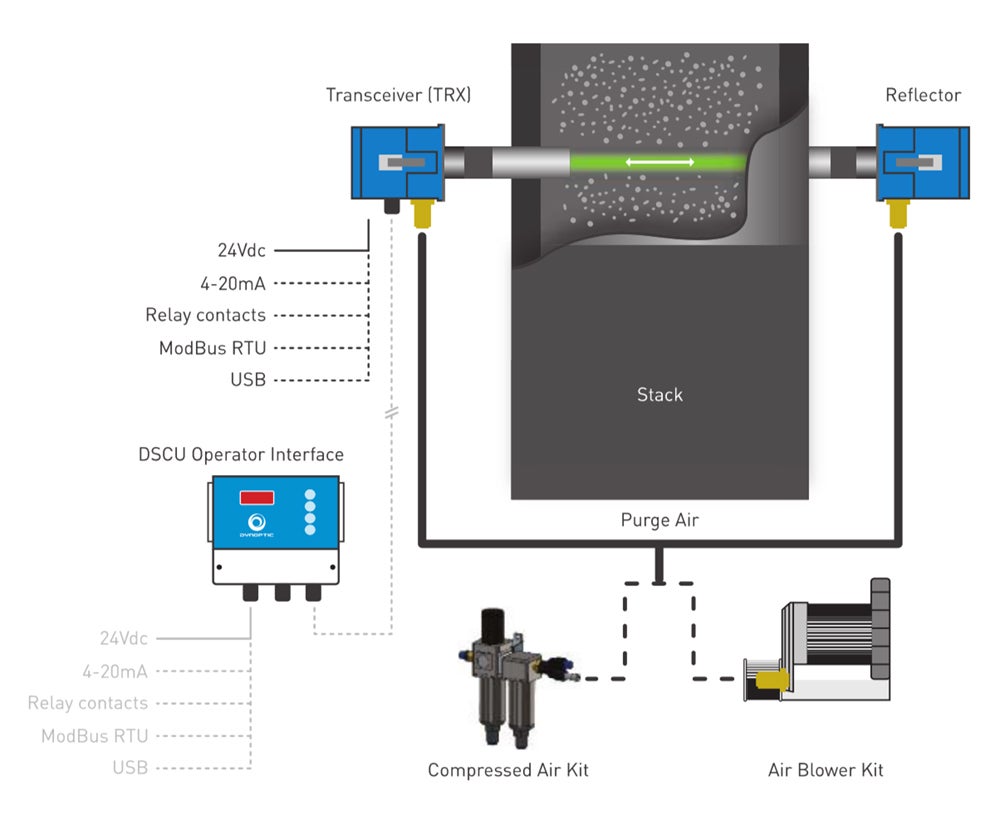

The DSL-460 uses the double pass light transmission measurement technique, with a folded beam Transceiver/Reflector arrangement. A light beam emitted from the Transceiver (TRX) passes across the duct, stack or flue to a Reflector, which then returns the light to the Transceiver where the intensity of the received light is measured.

Increased particulate density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity can be presented as % opacity or when calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m³.