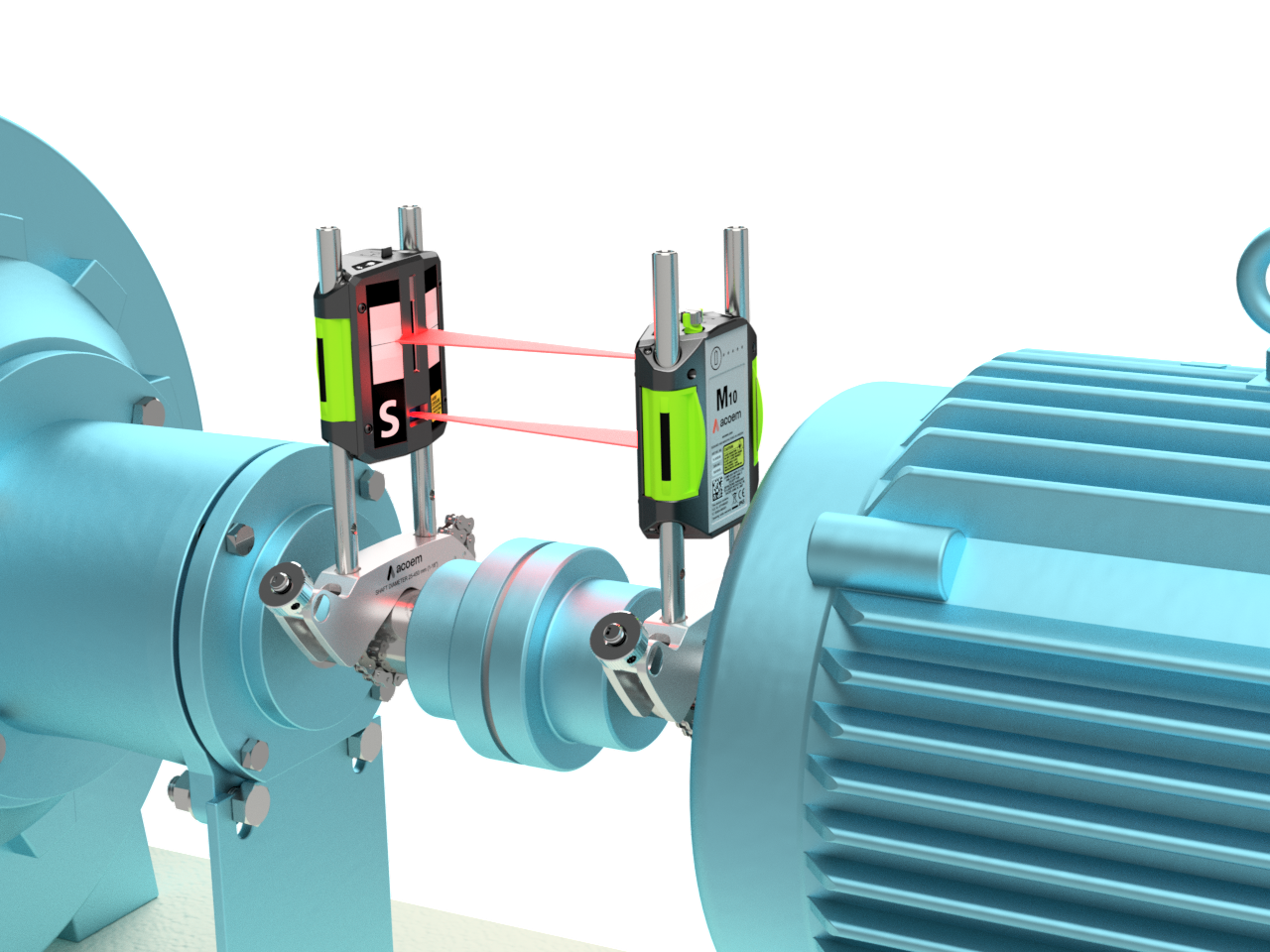

AT-300

Next-generation digital line laser system redefining precision and productivity in measuring methods.

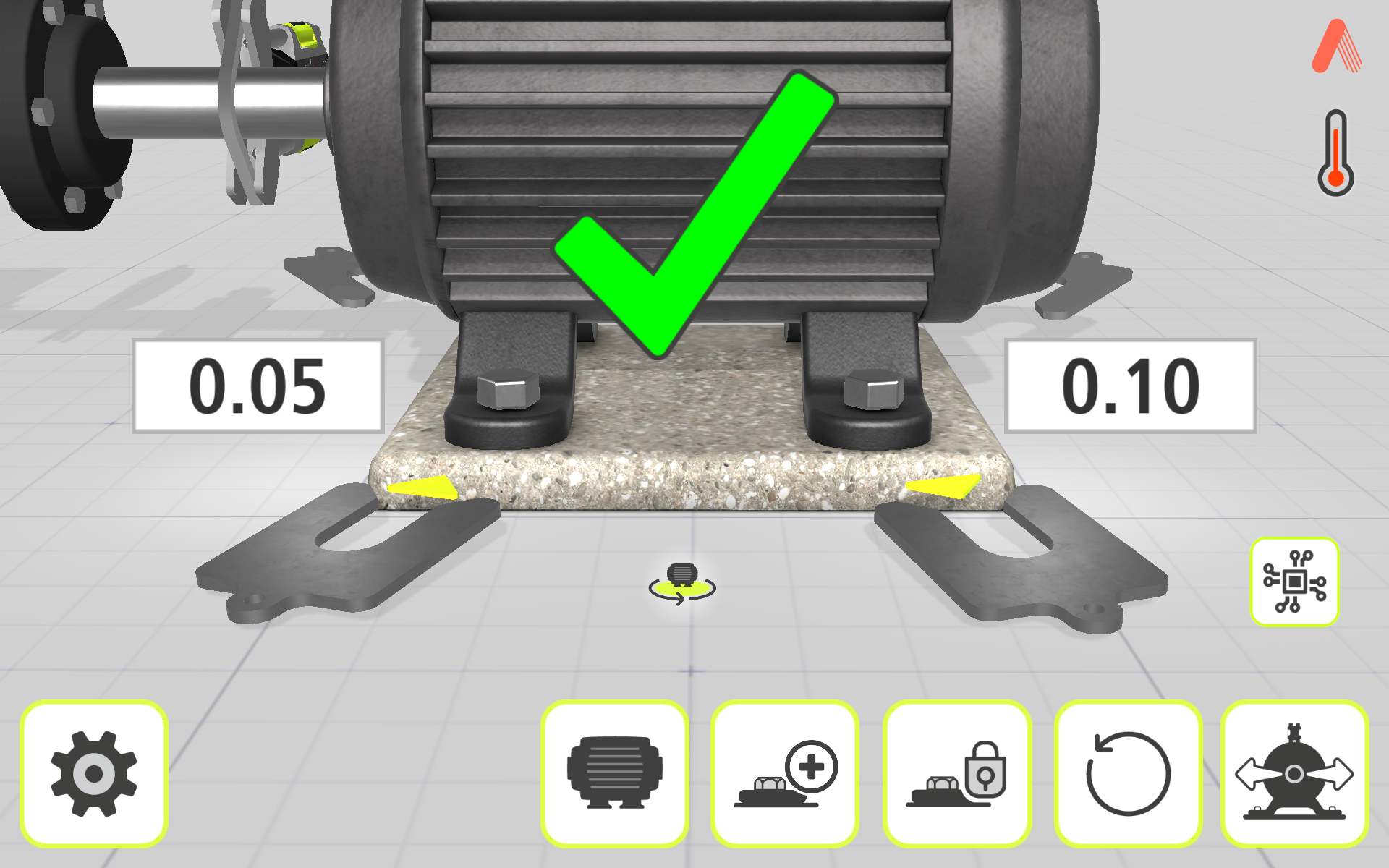

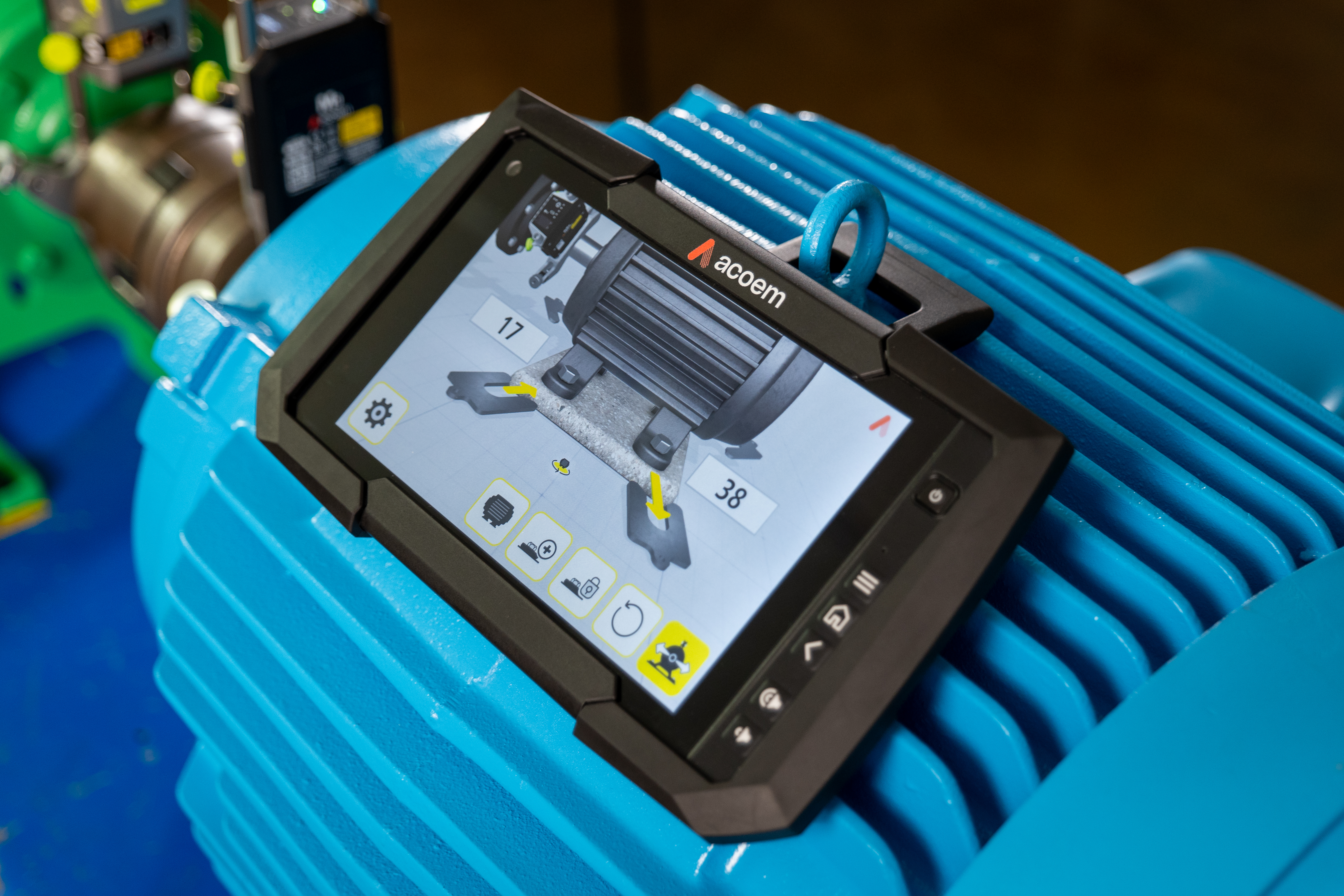

Welcome to the future of laser measurement technology with the Acoem AT-300, the next-generation digital line laser system engineered for exceptional performance. With extensive software functionality, a streamlined user interface, and intelligent sensor technology, the Acoem AT-300 is designed to revolutionize your experience across various applications.

At the heart of the Acoem AT-300 lies a commitment to excellence in various measuring methods. Our cutting-edge technology ensures swift and accurate results, enhancing both performance and precision. Say goodbye to guesswork and hello to precise measurements every time.