Grow your maintenance capabilities

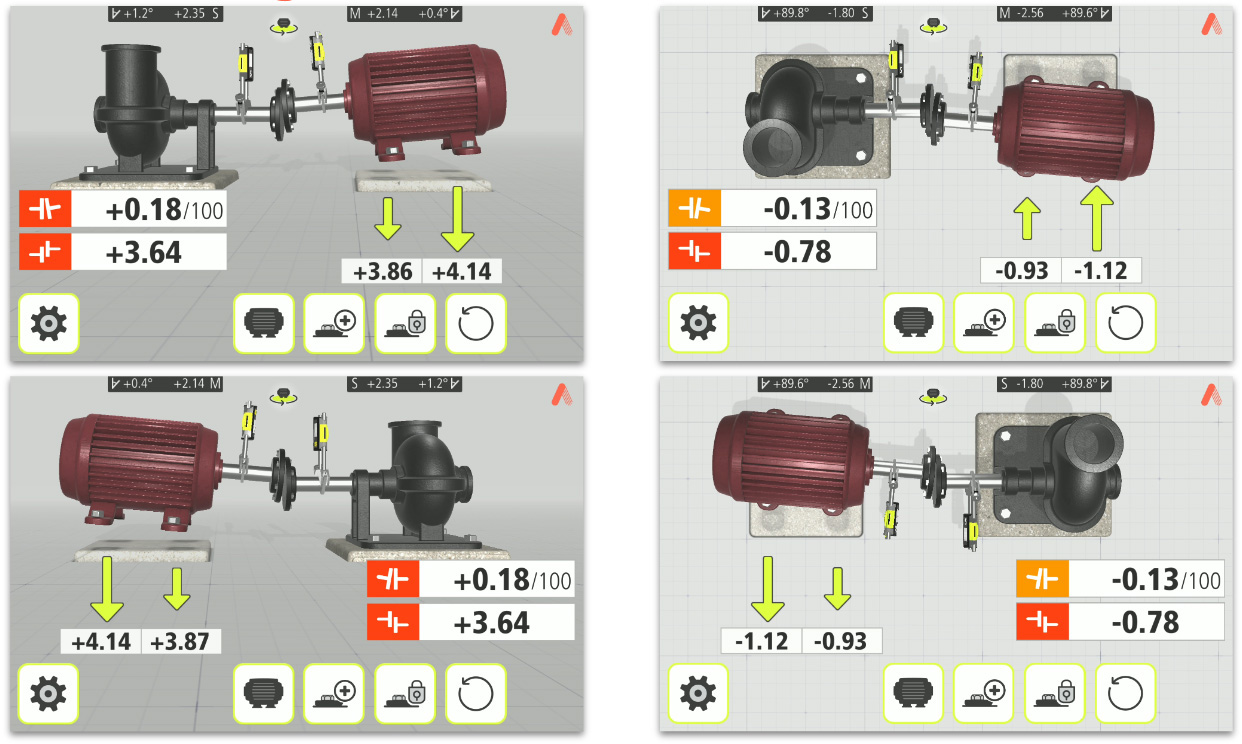

The Horizontal and Vertical shaft alignment apps are part of Acoem’s Augmented Mechanics Ecosystem, the first truly flexible and scalable solution for combining different technologies on the same mobile platform to deliver reliable and precise proactive and predictive maintenance for industrial machinery.

Designed to allow you to continually add to or upgrade as new technologies become available, or as your specific needs change over time, the Ecosystem is made up of a combination of mobile applications, connected wireless sensors.

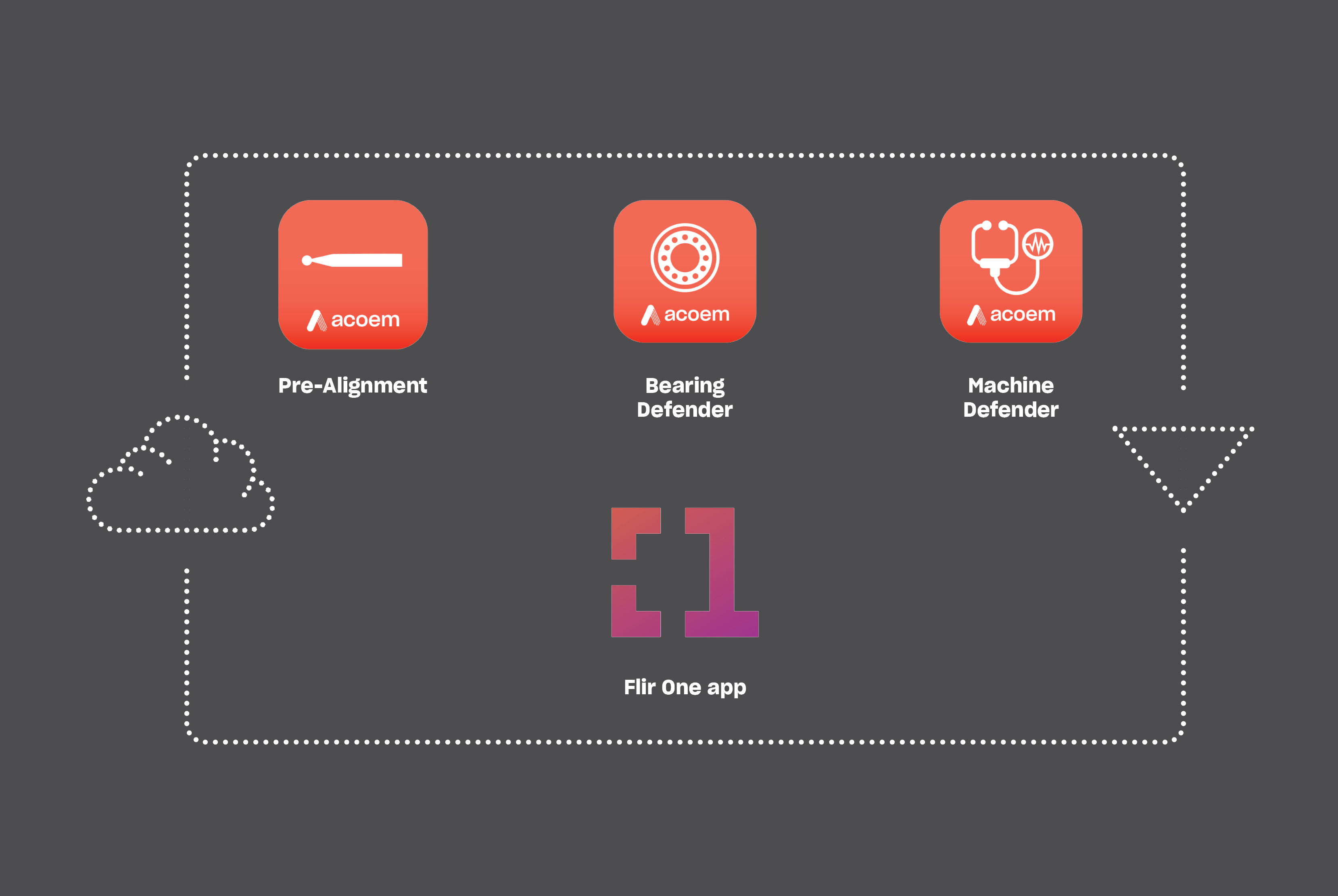

In addition to the Horizontal and Vertical shaft alignment apps, the Ecosystem currently features:

- The Pre-alignment app, designed to remove the complexity of your laser alignment process, making it faster and more reliable (works with the Acoem wireless Run-out probe)

- The Bearing Defender app, which provides quick first-level information on bearing health based on vibration readings in a matter of seconds (works with an Acoem wireless vibration sensor)

- The Machine Defender app, which provides full rotating machinery with AI-powered vibration diagnostics instantly in the field (works with an Acoem wireless vibration sensor)