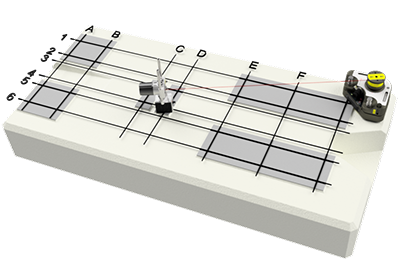

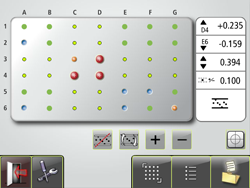

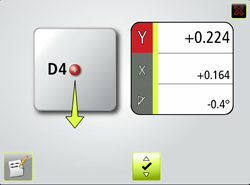

Rectangular flatness measurements

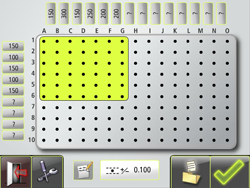

Stay square with the nxa geometry

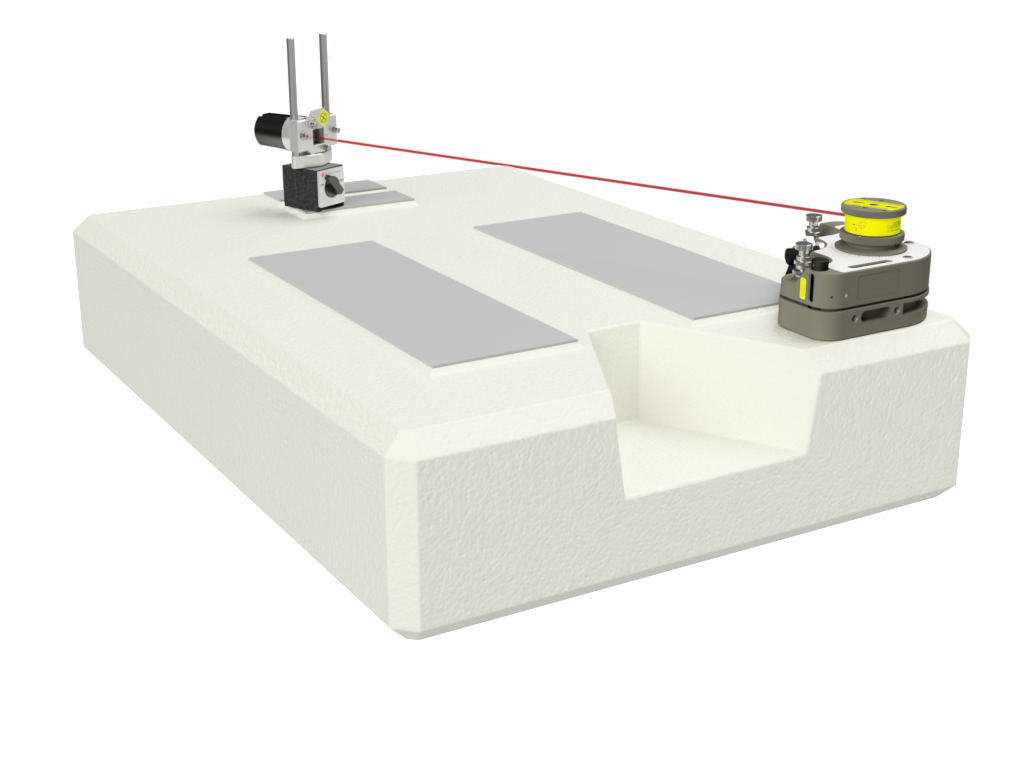

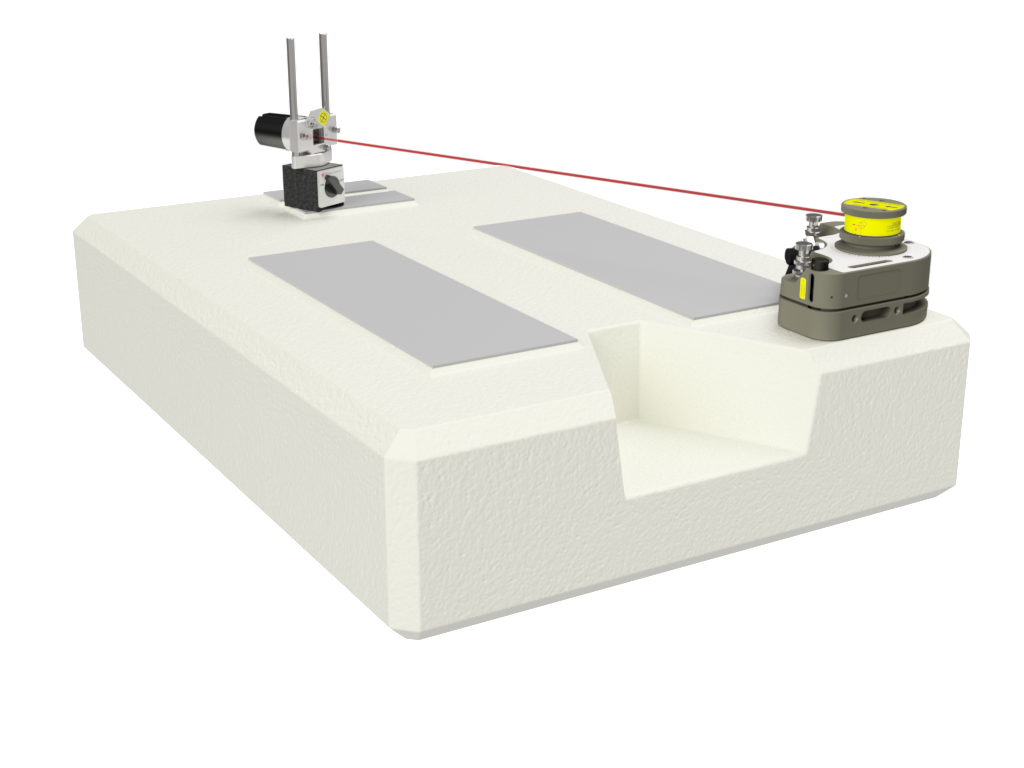

Typical applications are measurements of e.g. machine beds and machine foundations. For the latter application, it is particularly beneficial to combine flatness measurement with shaft alignment when installing rotating machinery. First, you check the foundation’s surface for possible irregularities, a so-called pre-alignment check. If any, adjust these. Install the machine and check for possible misalignment with a laser-based shaft alignment tool like the NXA Ultimate system.