During a recent training class, at a new gas plant, the class performed an alignment check on a 200 HP, 1780 RPM motor & overhung centrifugal pump. The motor/pump base is welded to the modular skid which also has the “B” backup pump to the “A” pump we were aligning. The electric motor for the “B” pump can be seen in the background of the photo below. Also, note that the motor/pump base is not supported in the middle. This modular skid is sitting on the ground and not anchored.

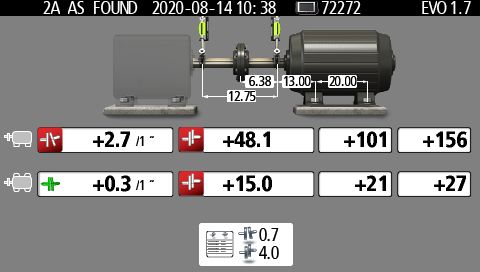

There was noticeable vibration felt on the skid, so we took several sets of alignment readings. Both the vertical and horizontal coupling values repeated.

This alignment check now became a precision shaft alignment as the vertical angularity of 2.7mils/1” is almost 4 times tolerance and the vertical offset (parallel) of 48.1 mils is 12 times tolerance. The mechanics started the Verti-ZontalTM Process by first completing the pre-alignment steps (soft foot, etc.) then correcting the vertical misalignment per the shim screen, consolidating the shim stacks while doing so. They then went “live” to correct the horizontal misalignment.

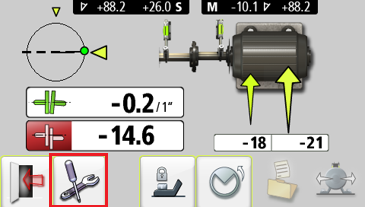

While performing the horizontal correction the coupling and feet values were changing. We activated the EVO’s Screen Filter which did “settle down” the live coupling and feet values somewhat though they were still changing slightly. The yellow arrows indicating the direction to move the motor were steady.

This was a first for me as I have activated the screen filter in the past which “steadied” the live values. I surmised the screen filter didn’t completely settle the live values, in this application, as the modular skid was not anchored, and the middle of the motor/pump base also is not supported. My thinking was the motor, with the feet loose, was moving differently (bouncy) than the components still bolted to the skid causing “odd” excessive movement.

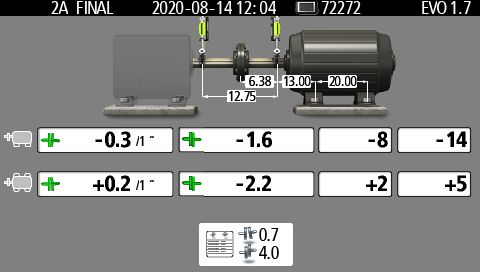

That being said, the mechanics adjusted the motor horizontally to close to acceptable tolerances then tightened the hold down bolts. Due to the coupling influences from the original gross vertical misalignment we figured there would be a touch up needed to the vertical position and did not worry about getting the horizontal position in tolerance at this point.

After the first Verti-ZontalTM correction was completed we remeasured with these results.

During the 2nd Verti-ZontalTM correction they adjusted the motor horizontally until the coupling values fluctuated just a few tenths of a mils (0.0001”) on either side of zero.

So, even with an unusual vibration issue the mechanics completed this precision shaft alignment (including pre-alignment steps) in one hour and 26 minutes and to excellent tolerances.

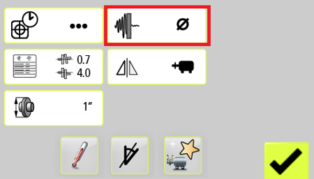

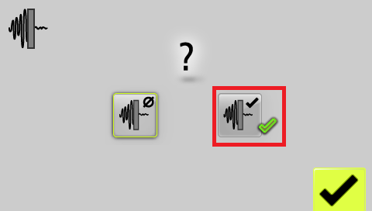

Is severe vibration causing you issues during a precision shaft alignment? If so, here’s how to access the Screen Filter on EVO, ECO & GO alignment systems. (The NXA Pro & NXA Ultimate screens are very similar).

The Adjustable Screen Filter is accessed from the tools screen while in the horizontal shaft alignment application. Select the Tools Icon at the bottom of the alignment screen. Then select the Screen Filter icon setting to activate or deactivate the screen filter.

NOTE – It is recommended to deactivate the screen filter for normal operation when not in severe vibration environments.

Having other troubles with a difficult precision shaft alignment?

We are happy to provide support! Contact us.