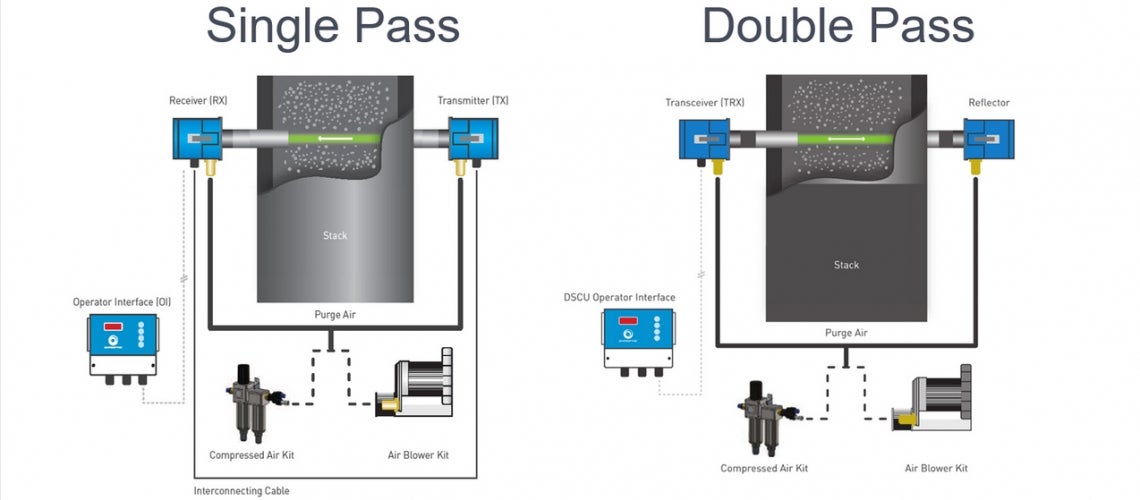

Features and characteristics of single pass monitors:

- Suitable for stacks up to 20m diameter

- Requires clean stack gas for calibration

- More suited to higher emissions levels

By comparison, the double pass light transmission measurement technique uses a folded beam transceiver/reflector arrangement. A light beam emitted from the transceiver (TRX) passes across the duct, stack or flue to a reflector. The reflector then returns the light to the transceiver where the intensity of the received light is measured providing either particulate or opacity readings.

Features and characteristics of double pass monitors:

- Suited to smaller diameter stacks up to 10m

- Calibration check while process is running

- No power required to passive reflector head

- More suited for lower emission applications

Acoem offer a range of monitoring technologies including both single and double pass light transmission monitors along with options and accessories to create a customised monitoring solution for your emission monitoring application. Please contact us for more information.