Acoem capability & capacity

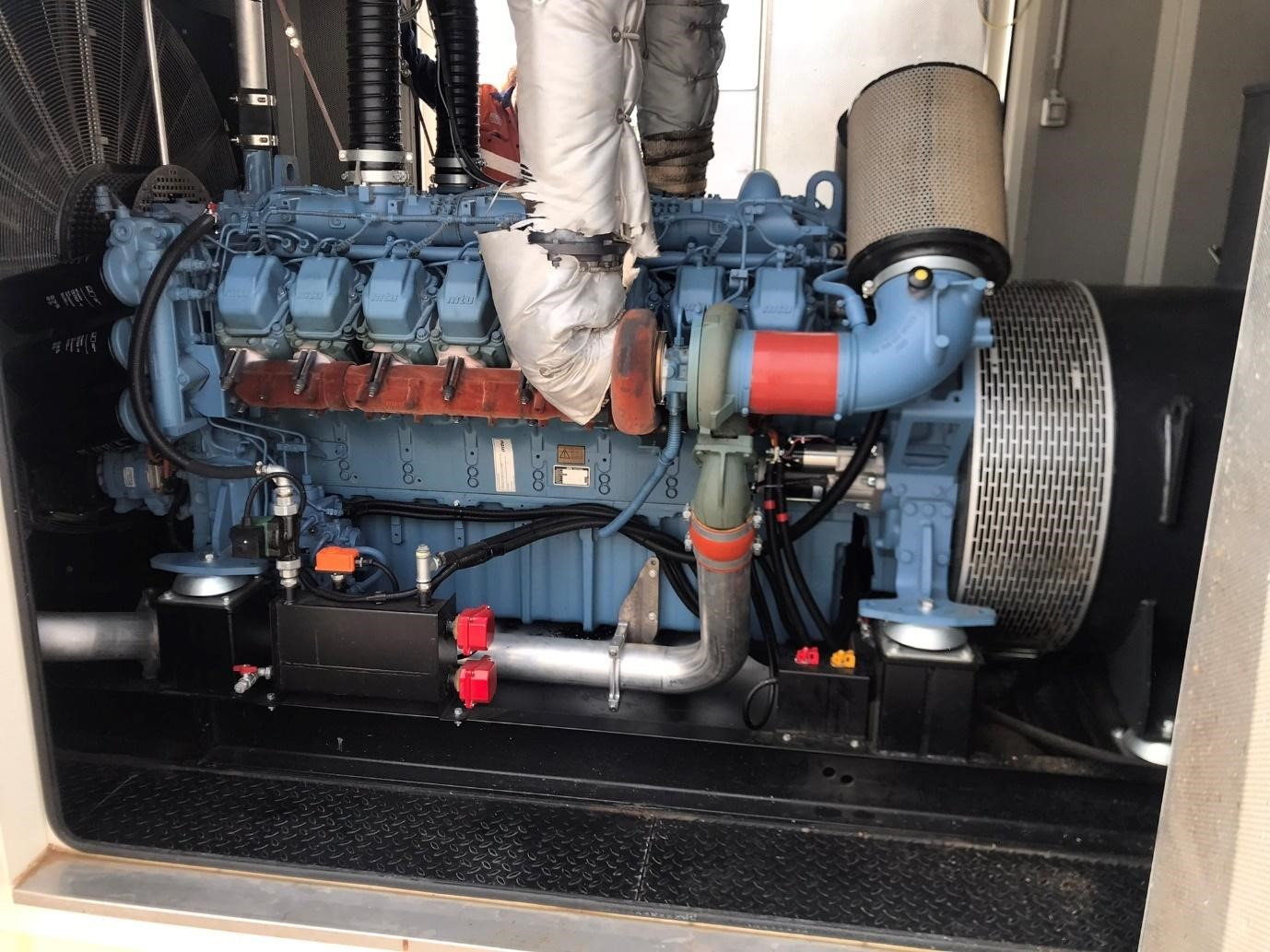

Ty’s thorough understanding of the machinery, coupled with the AI-driven automatic diagnostics of Acoem technology, led him to identify that the enclosure wasn’t installed correctly as per drawings, causing soft footing. A corrective action was raised to install a central footing to eliminate resonance. The remediation work performed resulted in much of the genset vibration being removed and most, if not all vibration, of adjoining fuel pipes. This and subsequent remediations led to an immediate and significant improvement in operational performance.

Fortunately, these proactive maintenance works helped the power station avoid complete machine failures and minimised the downtime required. Both Ty and this company’s management are hoping that reliability recommendations made by Acoem for future maintenance projects will help them avoid similar potential failures at their other power stations where structural fatigue can cause massive delays in production.

“I look forward to presenting this case study at the CBM + Reliability Connect conference and being able to share the positive results of this project with a wider audience – especially those that operate critical machinery and are looking to optimise their maintenance strategies,” commented Ty.

Ty will be presenting on Thursday, 16 November at 3pm. For further information, please contact Ty at ty.smith@acoem.com