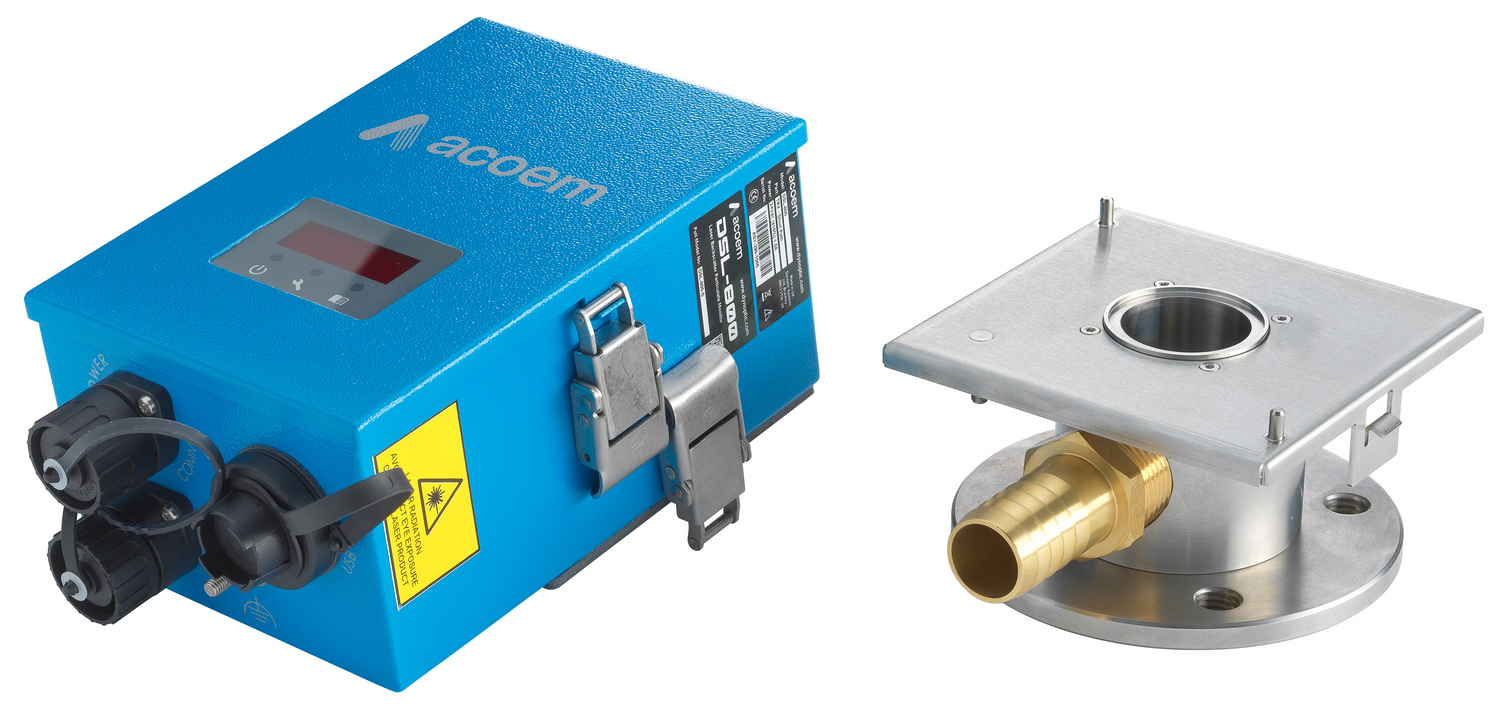

DSL-800

Precision emissions control at your fingertips

The DSL-800 is a laser backscatter optical instrument designed to monitor the concentration of particulate matter passing through a duct, stack or flue of industrial combustion or air filtration processes to provide in-situ measurement directly in exhaust gas flow.

It delivers accurate measurement readings, operating within a compliant performance range of 0-150mg/m3 when calibrated against standard reference measurements.