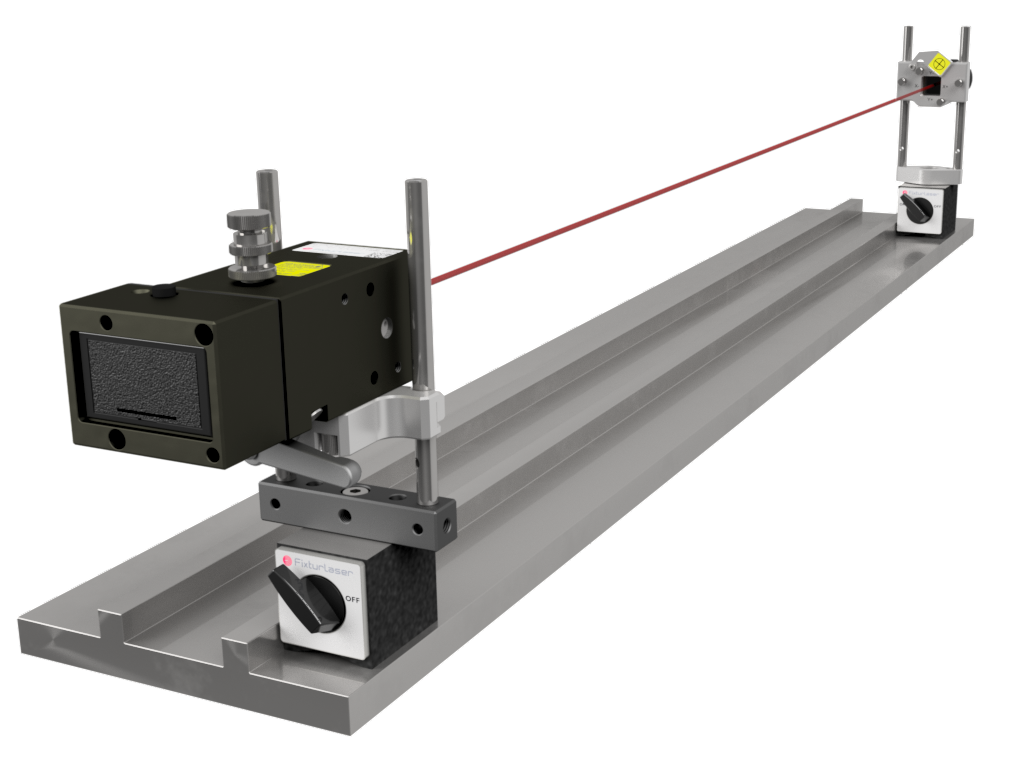

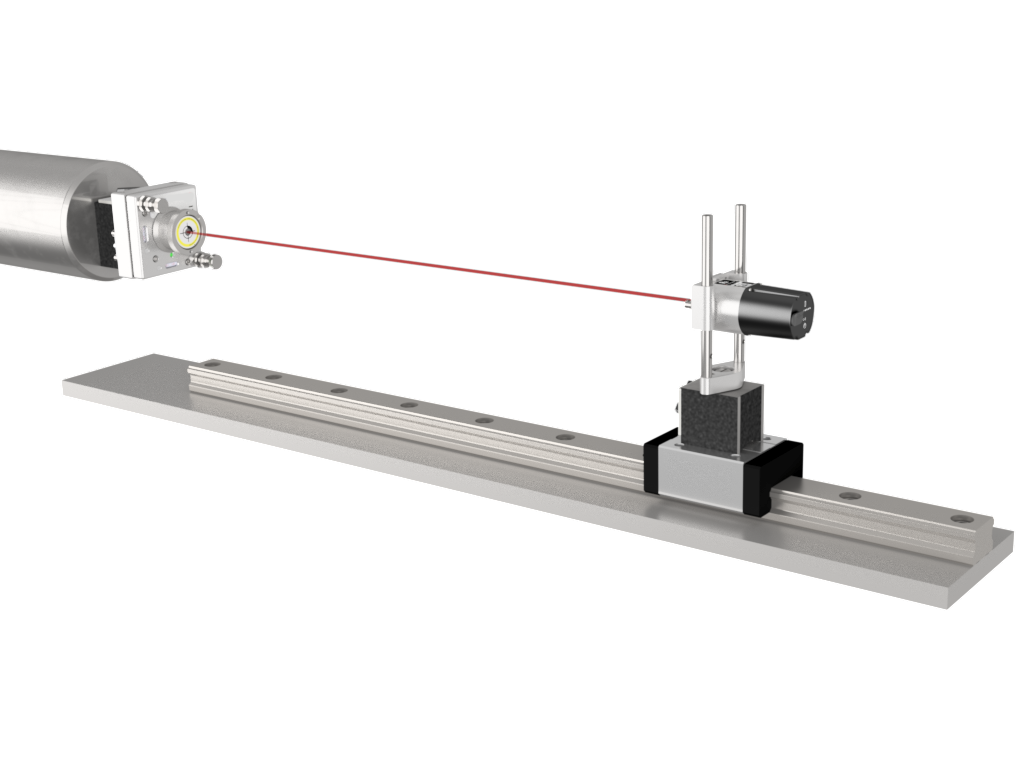

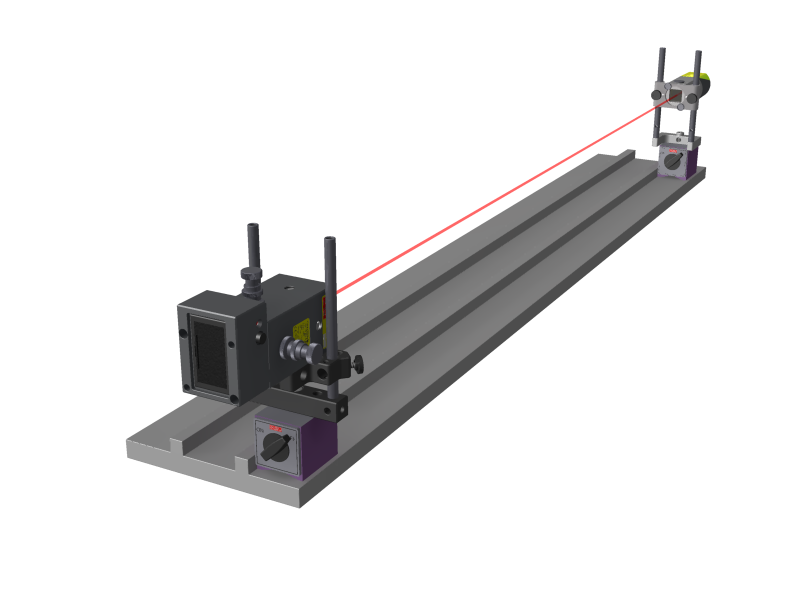

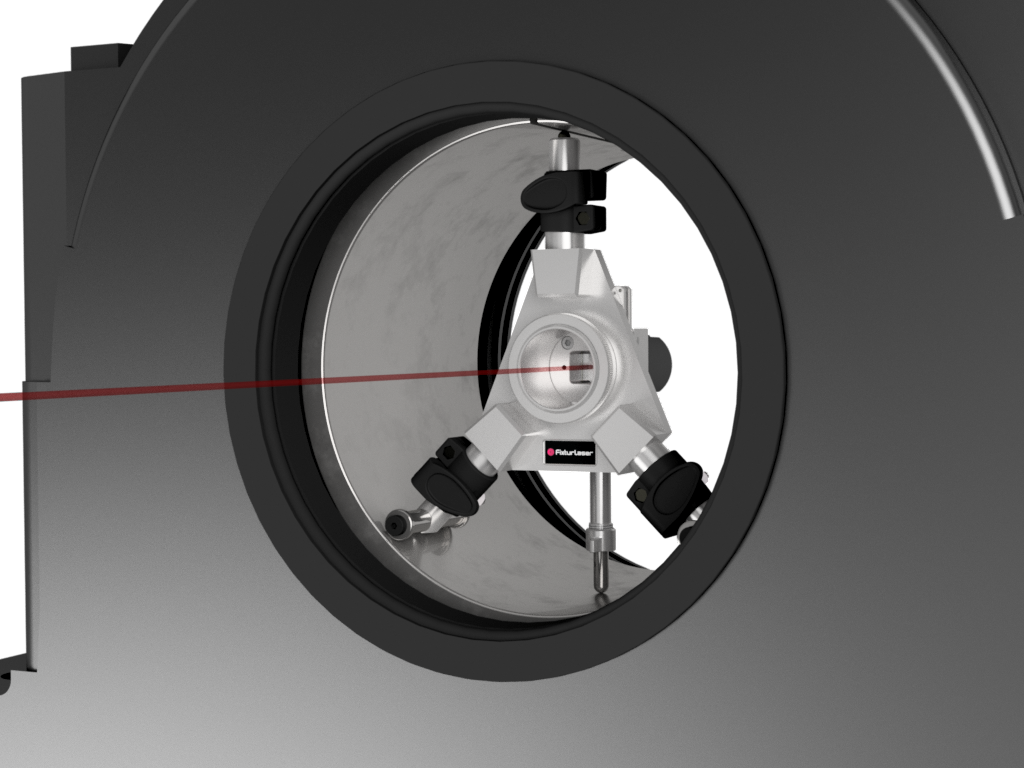

Straightness measurement

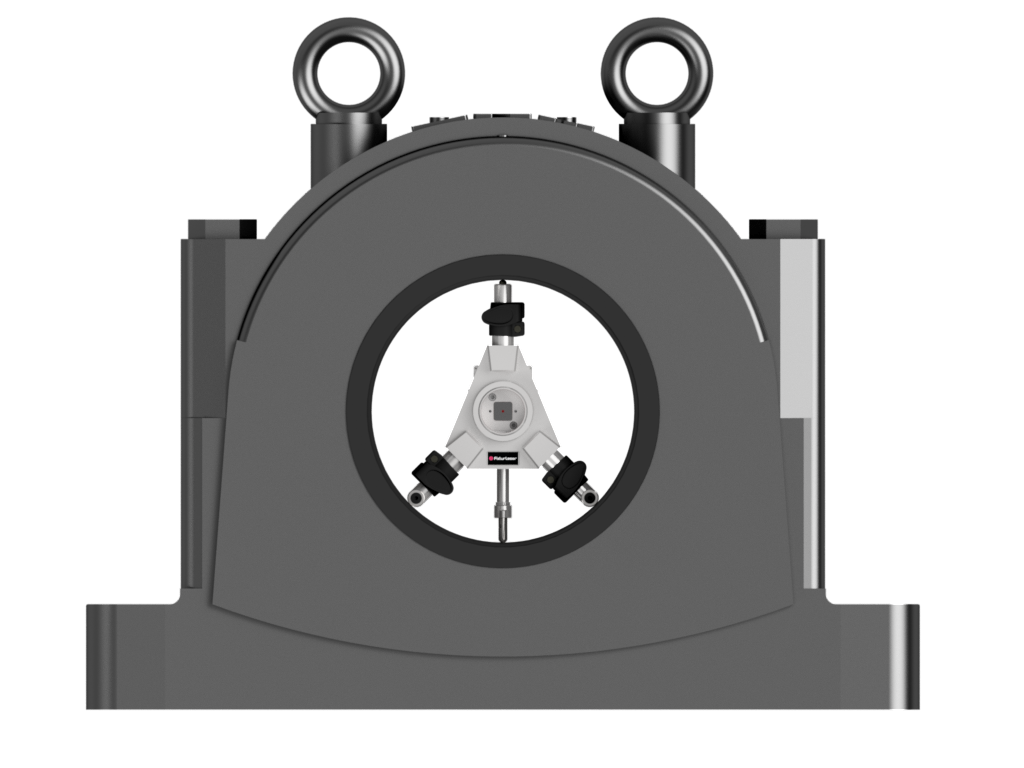

Straightness with an edge

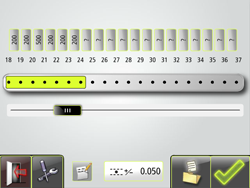

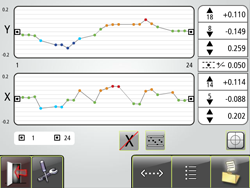

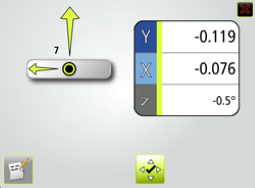

The straightness application is measured in two axes, where the laser beam is used as a reference. The deviation in distance between the laser beam and the measurement object is measured in two or more positions with the use of a receiver.