After completing precision shaft alignment training on the first day, the class used a EVO to measure the effects of tightening pipe flanges on the suction and discharge lines.

Here is the procedure we used:

We aligned the motor-pump to within tolerance, then aligned the pipe flanges to pump flanges using squares, to assure parallel and angular flange alignment, proper axial spacing for gasket, and verify flange bolts have free movement. The threaded rods were used to do this step.

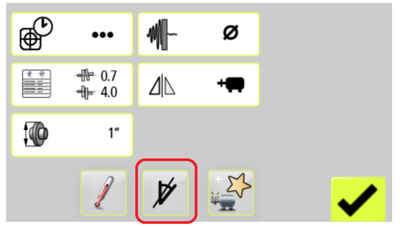

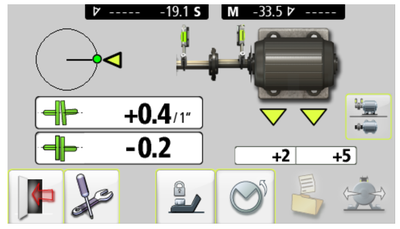

Before remeasuring the shaft alignment, we turned the inclinometer values off in the EVO. Typically, this is used when measurements are taken using the Clock Measurement Method, or when machines are installed on an incline.

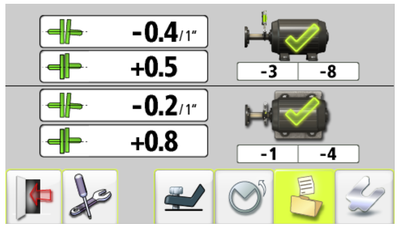

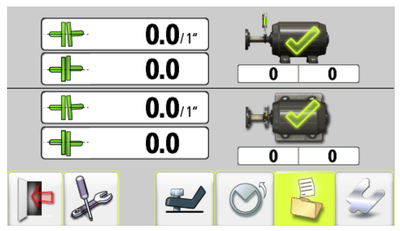

We took the three measurements WITHOUT rotating the shafts or moving the lasers. This gave us a zero values for the shaft alignment. NOTE: This is not the true shaft alignment, which was previously completed, but serves to zero the two laser heads to each other.

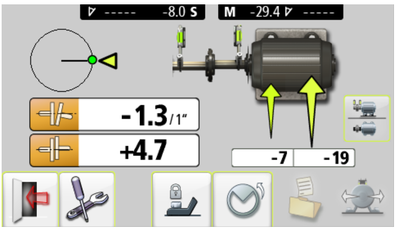

We began tightening the pipe flanges, starting with the 9:00 bolt on the suction flange. We did not measure the torque value, but I would consider this “snugging” the bolt. Note the change. This showed us that snugging the 9:00 bolt changes the alignment by almost 5 mils at the coupling as well as inducing angular misalignment.

Leaving the laser heads in place, we went to the 3:00 bolt, and snugged it to roughly the same amount. Doing so moved the pump back in the opposite direction almost back to zero. We then rotated the lasers to the 12:00 position, re-zeroed the lasers, and repeated this process for the 12:00 and 6:00 flange bolts. A similar movement was noted.

Snugging the remaining flange bolts caused very little movement of the shafts. The flange bolts were then tightened to specifications. A similar response was noted when tightening the discharge flange bolts. Rechecking the shaft alignment after tightening bolts showed the alignment is still within tolerance.

We documented the following:

- Tightening of flange bolts can cause movement of the pump, if not done carefully.

- Over-tightening of flange bolts, without snugging them first, would not bring shafts back into alignment.

- Following proper bolt tightening procedures on the flange can minimize unintended movement at the shafts.

- A good laser alignment tool can be effectively used to both measure and document alignment changes due to tightening flange bolts.